Advanced Tube and Sheet Metal Fabrication with No Limits

All-in-one tube processing technology and automated fiber laser cutting systems from BLM Group provide the flexibility to do work ranging from furniture, job shop, motorcycle and hydraulic pipe construction to automotive, aerospace, agricultural and recreational equipment.

Posted: September 9, 2019

In Booth D-46532, BLM Group USA Corporation (Novi, MI) will demonstrate how their all-electric 3-RUNNER modular tube forming machine can straighten, form, and cut from coil stock – all in one piece of equipment. It will be shown in the context of a complete production cell that includes tube bending and end-forming operations. This customizable machine can be configured to grow with company needs: Users can start from an initial system with straightening and cutting, then transition into a complete production process that starts with coil and goes through straightening, forming (up to six stations), facing, cutting and programmable unloading of the finished part – all in one continuous operation, with all machine movements managed by an electric axis and all part positions and power parameters saved together in the part program. No additional mechanical adjustments are required, helping the system achieve both fast setup and accurate positioning of all production phases and maximum repeatability. As an all-electric system, the 3-RUNNER simplifies wiring and eliminates hydraulics to reduce maintenance requirements and wear on tube forming components. It also reduces energy consumption to just 4 kW.

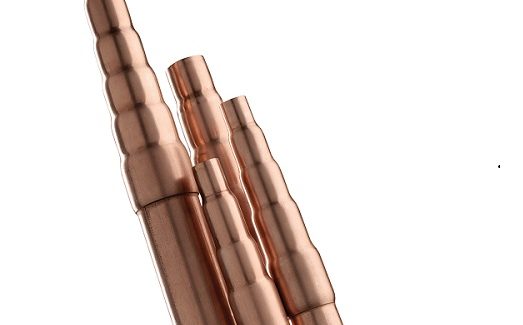

BLM will also demonstrate their E-TURN all-electric tube bender, capable of fixed and variable radius bending in right- and left-hand automatic cycles. Its all-electric drive ensures precision control of the 15-axes movement, providing consistency, high accuracy, perfect quality bends and zero scrap. Tubes in most materials and section types – including round, square, rectangle, flat sided oval and elliptical – can be automatically loaded, bent and unloaded. The flexibility, accuracy and speed of this bender makes it well suited for furniture, automotive, job shop, motorcycle and hydraulic pipe construction applications. A key differentiator of the E-TURN is the VGP3D programming and 3D simulation software. By simply inputting the component bend coordinates, the complete bending program is graphically simulated, highlighting potential collision risks and producing the optimal working cycle. Component feasibility is checked virtually, eliminating the need for prototype tooling or physical testing on the machine. Unloading of the finished component is also automatically managed by VGP3D, with 180 deg head rotation allowing the component to be unloaded in the position required.

Changeover times are significantly reduced and machine setup is simplified as all the critical settings for the machine tooling are managed automatically by the CNC, including clamps, pressure die, mandrel position, retraction, center line radius, etc. Additionally, the self-calibration feature enables true simultaneous axis movement with automatic adjustment of these settings. The all-electric technology of this bender reduces power consumption, typically offering 80 percent savings over conventional hydraulic bending machines. Maintenance is also reduced through simplified cabling and components. The E-TURN is available in four sizes capable of handling maximum tube OD capacity ranging from 30 mm x 2 mm (1.18 in x 0.079 in) up to 50.8 mm x 1.5 mm (2 in x 0.059 in). Depending upon the system, the E-TURN provides a minimum bending radius of 25 mm to 35 mm and a maximum bending radius of 150 mm to 165 mm.

BLM will also demonstrate their ELECT150 all-electric tube bender that accommodates tube diameters up to 150 mm (6.0 in). With multiple tool stack capability, it can produce fixed and variable radii in a single setup. The all electric operation of this bender provides energy efficient production and eliminates the need for hose and piping associated with hydraulic systems to simplify maintenance and improve reliability for more consistent bending. This 12-axis system is well-suited for tube production in a variety of industries, including automotive, aerospace, agriculture equipment, and recreational equipment. A maximum of up to eight tool sets can be mounted simultaneously within the stack height. Either automatic or manual loading is available, with the ability to position the automatic loader to the left or right of the machine. Additionally, a special loading cycle is available for heavy tube or multi-ball mandrels. The ELECT150 can incorporate automatic tube bundle loading and a handling robot for a complete turnkey solution that manages the entire tube loading and unloading sequence.

A key differentiator for all BLM benders is VGP3D three-dimensional programming software that manages the entire system from a single point. Using part geometry data or 3D CAD data, VGP3D creates a part program, checks for part feasibility and calculates the real cycle time. By simulating the machine, tooling and the part bending sequence, it eliminates the risk of collisions, which typically occur during a first test run. Additionally, the machine automatically considers material composition and calculates the behavior of the part to minimize waste and guarantee part repeatability, process control and accuracy, even for complex parts. Part marring that can be caused by slippage at the end of a bend or wear tool is also reduced. All part bend positions, tooling information and power parameters are saved within the part program, providing easy recall of the recipe when a job is repeated. This guarantees quick setup and changeover and provides lot to lot repeatability.

BLM will also demonstrate their next-generation LT7 Lasertube machine that improves productivity and accuracy with 3D cutting capabilities and innovations in tube management and handling. The machine features a 3 kW fiber laser that provides a broad working range for easily cutting round, square or rectangular sections up to 6 in diameter. Special sections and open profiles can also be processed. Loading chains can be extracted from the rear standard bundle loader within seconds, providing the flexibility to load a single bar or open section quickly and simply. The loading and unloading systems also adapt to accommodate short and long parts with innovative tube supports throughout the process. At the end of each production batch, the LT7 automatically configures itself for the next batch for quick changes in production and higher productivity, regardless of the new sections to be made – round, square, special and even open profiles. No manual adjustments are necessary. This advantage results in higher output and a lower cost per part.

The LT7 further supports productivity and quality enhancements through its mechanical rigidity, which allows high levels of acceleration without compromising accuracy. Enhancements include these patented technologies:

- Active Scan – eliminates errors induced by distorted tubes.

- Active Tilt – uses focus head movement to provide fastest processing of small features.

- Active Focus – provides error free cuts regardless of changes of material and thickness.

- Active Marking – offers dynamic part marking for complete production traceability.

- Active Speed – ensures higher cutting quality on the most critical jobs.

- Active Piercing – increases piercing speed and reliability even on inconsistent material quality and thickness.

Two exclusive software programs enhance the versatility of the LT7 Lasertube to help keep production under control and bring design ideas to life: Protube and Artube. The Protube monitoring system helps users make accurate time and cost estimates based on processing time for an entire production batch. This system also prepares work orders and sends them to the machine while a remote management feature provides real-time production progress monitoring, system operating statistics, estimates to the next batch change and more. Protube can be integrated with an ERP system to automatically distribute work orders to all connected BLM machines and technologies. Artube is 3D CAD/CAM software that allows users to move from a design idea to a part in one click: simply enter tube dimensions to desired cuts to go straight to production. This software can also design a more complex frame through clear three-dimensional graphics, or users can import other CAD programs and send everything needed to start production to the machine immediately, without errors.

In Booth A-2153, BLM will demonstrate the LT-FREE 5-axis system for laser cutting bent and hydroformed tubes, flat and deep-drawn sheets and welded assemblies. With laser power up to 3 kW, table dimensions of 1,500 mm x 1,000 mm and axes strokes to X= 2,950 mm, Y= 950 mm, Z= 750 mm, C=continuous and B=140 deg, it’s ideal for machining mild steel, copper, aluminum, brass, stainless steel and galvanized steel. There are no limits to part access. Trimming and feature cutting can be achieved right on the bend, accurately and repeatably. The LT-FREE is extremely easy to use and efficient: Just select material type and thickness from the intuitive controller and the machine will automatically set all of the cutting parameters and the optimal focus position. Traditional cutting, drilling, punching, milling and deburring operations – normally carried out in sequence – can now be performed on a single machine to eliminate set up, reduce material handling, eliminate work-in-progress inventory and streamline the entire production process. Different material handling configurations are offered to meet specific production needs, while always guaranteeing the flexibility and productivity typical of this 5-axis laser cutting system:

- Entry Level – Two fixed workpiece tables for batch processing of bent tubes, hydroformed, stamped, and flat sheet.

- Mid Flex – Equipped with dual shuttle tables that automatically shift in and out of the laser work zone, making it possible to load/unload and laser process parts at the same time. Processing alternates between the two tables so production can run uninterrupted.

- One Flex – A fixed table and robot make this version ideal for processing large pieces for low-volume, high mix production.

- High Flex – A dual robot coupled with dual-shuttle tables offer high productivity because the loading and unloading takes place without interrupting the cutting process.

- Piece Value – A large rotary indexing table offers efficient and continuous production.

The system is equipped with a user-friendly CAD/CAM software to create part programs of any complexity in a simple 3D graphical environment.

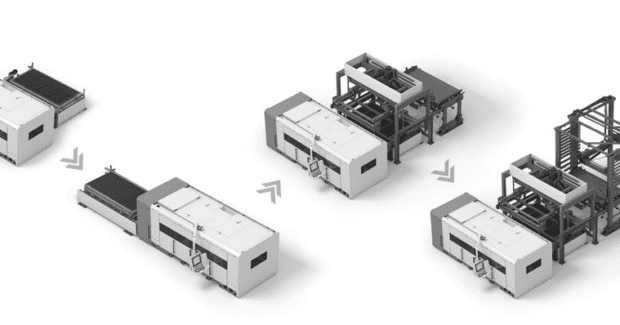

Also on display will be the LS5, the only modular sheet laser cutting machine that can be expanded to accommodate tube cutting functions at a future time. A very compact machine with a configurable design, it accommodates a transverse or in-line pallet changer. Users can add automatic sheet loading and unloading or a storage tower for automated material type and thickness changeovers – a feature that will be demonstrated during the show. Also on display will be the quick nozzle changer feature for minimizing setup time when changing materials. The LS5 is available in powers up to 8 kW and comes in bed sizes of 10 ft x 5 ft, 13 ft x 6.5 ft, and 20 ft x 6.5 ft. The fiber laser makes it appropriate for cutting reflective materials, such as copper, brass and aluminum, as well as mild, stainless and galvanized steels.

BLM Group USA Corporation, 46850 Cartier Drive, Novi, MI 48377, 248-560-0080, sales@blmgroupusa.com, www.blmgroup.com.