All Position Welding and Cutting Travel Carriage

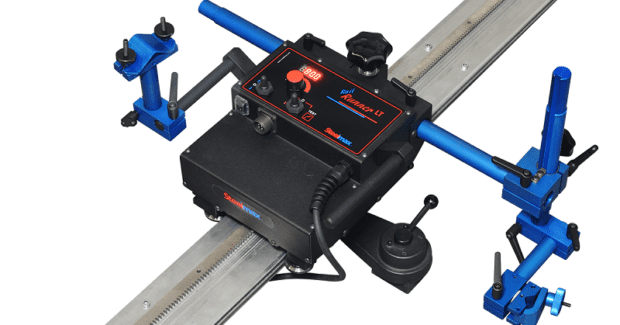

The digitally-controlled, rail-mounted Rail Runner LT travel carriage from Steelmax mechanizes welding and thermal cutting processes for extremely economical welding and cutting applications on flat or curved plate, tube and pipe.

Posted: September 26, 2019

In Booth B-33050, Steelmax Tools LLC (Centennial, CO) introduces their Rail Runner LT, an extremely economical system for welding and cutting applications on flat or curved plate, tube and pipe. This digitally-controlled, rail-mounted travel carriage is designed for the mechanization of welding and thermal cutting Rail Runner LT,processes. Mechanized control of the welding or cutting torch allows continuous welding or cutting, increasing operating factor and deposition rates in welding applications. The Rail Runner LT features a rack-and-pinion drive system with electronic speed control that produces weld bead geometry exactly to your required specifications, reducing costly over-welding and minimizing filler metal usage. The Rail Runner LT can be used with semi-flexible rail for plate and tank applications with a minimum diameter of 32 ft (10 m) and can be adapted to ring rails for pipe and tube applications.

Standard ring rails are available for tube diameters from 8 in (200 mm) up to 10 ft (3 m). Custom-rolled rails can be used for tube diameters between 10 ft (3 m) and 32 ft (10 m). An optional vacuum system allows the rails to attach to non-ferrous surfaces such as stainless steel and aluminum. Application specific accessory kits for oxy-fuel, plasma, MIG/MAG and SAW processes are available.

Also on display will be their Eco Runner Trackless Welding Carriage, a battery-powered welding travel carriage designed to produce continuous fillet welds using MIG/MAG torches in the flat or vertical welding positions. Providing mechanized motion of the welding torch, the Eco Runner allows for continuous welding which increases operating factor and weld deposition rates. This state-of-the-art portable cutting and welding system boasts a four-wheel drive system and permanent magnetic base that provides powerful traction, smooth travel and stable speeds. A digital speed readout insures repeatability of the weld procedure and produces weld bead geometry exactly to required specifications, reducing costly over-welding and substantially decreasing filler metal usage. A quick disconnect torch holder allows the torch to be easily swapped from one side of the Eco Runner to the other, enabling the operator to weld the entire workpiece from end to end.

The Eco Runner adds flexibility with built-in guide rollers, a footprint designed for welding in narrow spaces, and a host of accessories, such as auxiliary magnet blocks and an optional power supply that can be used to plug the carriage into a 115V to 230V power source.

Also being introduced during the show will be the D1 Low Profile Mag Drill, an ultra-low-profile mag drill that fits in the tightest of work spaces. It weighs only 21 lb and is the perfect solution for any application in confined spaces where typical mag drills are too large. A powerful motor and strong, electromagnetic base enable drilling of holes up to 1-7/16 in (36 mm) diameter to a depth of up to 1-3/16 in (30 mm). This drill accepts both TCT and HSS cutters, as well as twist drill bits with a standard ¾ in Weldon shank. The drill has an emphasis on durability, safety and portability, featuring an integrated swarf guard, Magnetic Field Shape Control (MFSC) and a lifting handle for easy transportation.

Steelmax Tools LLC, 15335 East Fremont Drive, Centennial, CO 80112, 303-690-9146, www.steelmax.com.