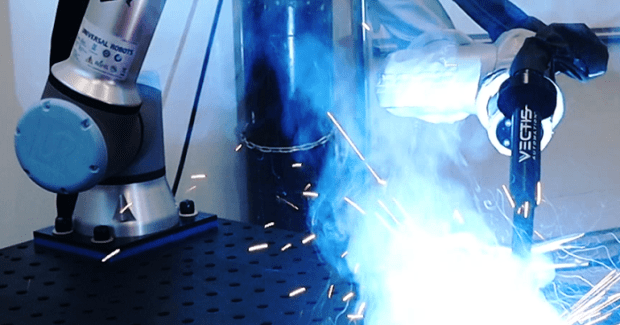

Cobot Welding Tool Boosts Productivity Amid the Shortage of Skilled Labor

Powered by a UR10e collaborative robot from Universal Robots, the Vectis Cobot Welding Tool from reduces the learning curve, setup time, risk, and cost of robotic welding.

Posted: September 26, 2019

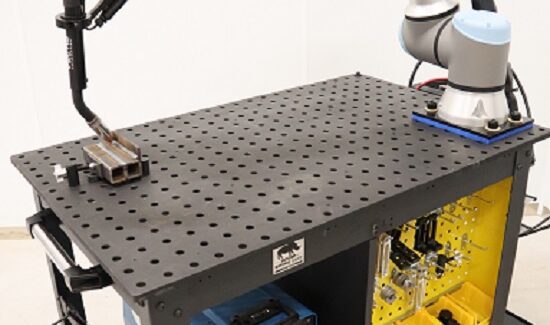

In Booth B-35083, Universal Robots USA Inc. (Ann Arbor, MI) will display the Vectis Cobot Welding Tool that helps manufacturers boost productivity amid the shortage of skilled labor by reducing the learning curve, setup time, risk, and cost of robotic welding. Powered by a UR10e collaborative robot, this tool is portable, safe, versatile, and extremely easy-to-use. Most users are setup within an hour of system arrival and welding within ten minutes of setup – with no programming experience necessary. Vectis’ DIY install, setup, and Let’s Weld Together™ intuitive programming interface saves shops valuable time and money because there is no need to fly to the Vectis facility for training, nor pay a tech to come on-site. The system is fully integrated onto a 3 ft x 6 ft mobile modular fixturing cart that enables metal fabricators to bring the cobot to the work or the work to the cobot, with no anchoring nor dedicated footprint required. The Vectis Cobot Welding Tool does not need three-phase power but runs off a 120V wall outlet, the welder can run on anything between 208V and 575V – including 240V single phase.

Vectis’ 30-day return policy, rent-to-own program, and fast lead times provide manufacturers with peace-of-mind to quickly start automating simple, repetitive parts and freeing up manual welders for more complex weldments or other value-add tasks.

Universal Robots USA Inc., 5430 Data Court, Suite 300, Ann Arbor, MI 48108-8944, 844-462-6268, www.universal-robots.com.