Fully Automatic, Unmanned Band Sawing

For steel fabrication and cutting complex shapes, the fully automatic AV-2026NC vertical tilt frame band saw with automated feeder table from Cosen Saws allows operators to push a button and walk away until the job is completed.

Posted: September 17, 2019

In Booth A-5325, Cosen Saws (Charlotte, NC) will feature their AV-2026NC band saw, an answer to the call for more automation in structural steel fabrication. The AV-2026NC combines a vertical tilt frame saw with an automated feeder table to create an advanced, fully automatic sawing system that allows operators to push a button and walk away until the job is completed. With a capacity of 20 in x 26 in at 90 deg and the ability to feed up to 59 in per single shuttle, the AV can be programmed to index up to 999 in of material. Its rigid tilt-frame saw head can easily cut angles between 60 deg in both directions, making this saw a perfect fit for steel fabrication and cutting complex shapes.

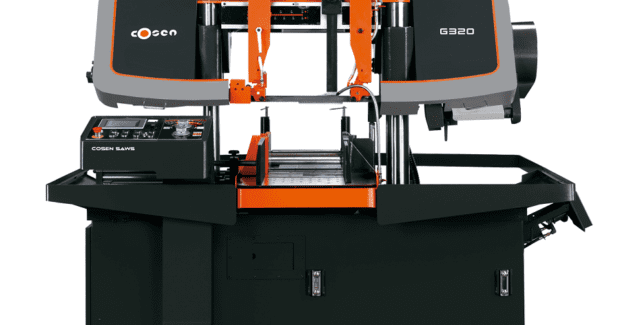

Also on display will be G320 fully automatic dual column band saw, a premier combination of rigidity, state-of-the-art software, technology and affordability. This saw utilizes a true stainless steel dual column design and is perfect for cutting in high production settings. Paired with V Drive technology, the G320 can easily improve operator efficiency and cut results, as well as help reducing cost per cut. The saw allows for a round capacity of 12.8 in, a rectangular capacity of 12.8 in x 15 in and comes standard with a quick-approach bar system and Save-A-Blade feature. The saw also comes equipped with the NC-Control system. Operators can store up to 100 cutting jobs, index material up to 999 in and easily control work flow all from an easy to use HMI touchscreen display.

Cosen Saws, 4527 Dwight Evans Road, Charlotte, NC 28217, 704-943-1030, marketing@cosensaws.com, www.cosensaws.com.