Going the Extra Step in Production Metal 3D Printing

Protolabs launches new production capabilities for their metal 3D printing service that use secondary processes to improve the strength, dimensional accuracy and cosmetic appearance of metal parts.

Posted: September 5, 2019

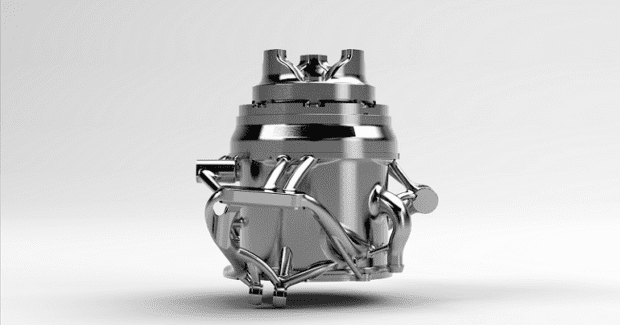

In Booth A-4350, on-demand digital manufacturing company Protolabs, Inc. (Maple Plain, MN) launches new production capabilities for their metal 3D printing service that use secondary processes to improve the strength, dimensional accuracy and cosmetic appearance of metal parts. As part of the launch, enhanced inspection reporting is also available. “We see it every day. The designers and engineers we work with in industries like aerospace and medtech are choosing additive manufacturing for complex components in high-requirement applications,” said Greg Thompson, the global product manager for 3D printing at Protolabs. “These new production capabilities help them optimize their designs to enhance performance, reduce costs, and consolidate supply chains – and do so much faster than ever before.” Protolabs uses direct metal laser sintering (DMLS) technology that is ISO 9001 and AS9100D-certified to 3D print metal production parts. Once parts are built, several secondary options – such as post-process machining, tapping, reaming and heat treatments – are possible, and quality control measures like powder analysis, material traceability and process validation are taken.

This production launch advances industrial 3D printing beyond prototyping: “We’re committed to servicing our customers’ needs throughout the product life cycle, across both conventional and additive manufacturing processes,” explained Thompson. A number of recent steps taken to reinforce this commitment includes joining the GE Additive Manufacturing Network and the MIT Additive Manufacturing Consortium, along with teaming with Wohlers Associates, Inc. (Fort Collins, CO) for an immersive 3D printing design course. Protolabs also added capacity to support their growth, with more than 25 GE Additive Concept Laser Mlab and M2 machines for DMLS production.

During the show, Protolabs will also introduce a new precision color-matching system in their plastic injection molding service that enables them to mold plastic parts in nearly any color within days: PolyOne’s PINPOINT™ Express Color and Dosing System, featuring 3M precision dispensing and dosing technologies, allows Protolabs to develop custom colors on site, drastically reducing the time it takes to mold short-run plastic parts in precise colors. When a part design is ready, customers can specify which Pantone number they require or simply provide a sample part that can be scanned and color matched. Once a material is selected from 13 available resin combinations, the PINPOINT system creates a liquid formula that is dispensed and mixed before moving to the injection molding press. The material is then fed through the doser and injection molded. The result is parts delivered – in custom colors – in customers’ hands within days, as opposed to the weeks it traditionally takes.

“These new color-matching capabilities are a huge leap for the manufacturing industry, one stacked with benefits for our customers who are developing highly tailored products,” noted Joel Matthews, a global product manager at Protolabs. “With development cycles shrinking to meet the market demand for increased customization, this is yet another tool to help shops accelerate product launches and streamline supply chains.” Protolabs also recently added new injection molding capabilities to further their position as a single-source supplier from prototyping to production. Along with custom color-matching, they launched numerous secondary processes and finishing options to support true end-to-end manufacturing, including pad printing and laser engraving, threaded inserts, mold texturing for Mold-Tech finishes, and part assembly. “These new capabilities are things that shops have wanted for a while, so we’re excited to finally be able to offer it to them while still delivering finished parts at industry-leading speeds,” said Matthews.

Customers seem to agree: “Speed and flexibility – being able to deploy different manufacturing options – and a commitment to customer service are the main reasons we use them,” explained Andy Homyk, a senior engineer at HemoSonics, LLC (Charlottesville, VA), a medtech firm that incorporated secondary processes to launch their new medical device in a fraction of the time that traditional manufacturing would have taken.

Protolabs, Inc., 5540 Pioneer Creek Drive, Maple Plain, MN 55359, 877-479-3680, www.protolabs.com.