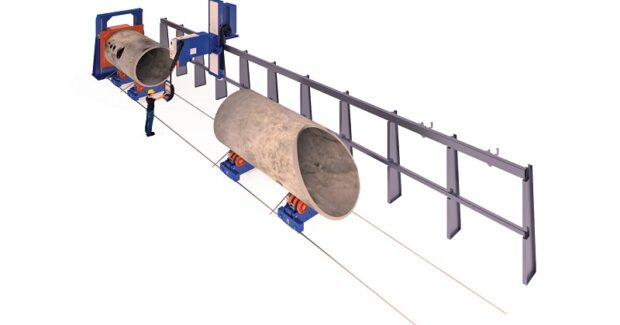

Highly Productive Cutting of Large Pipe Diameters and Heavy Weights

Extremely robust SPC 1500-3000 Pipe Cutting Machines from HGG guarantee precision cutting tolerances during the cutting of handle large pipe diameters and heavy weights for fabricating vessels and offshore production.

Posted: September 24, 2019

In Booth B-29094, HGG Profiling Equipment (Medina, OH) will feature HGG SPC 1500-3000 Pipe Cutting Machines that are extremely robust, handling large pipe diameters and heavy weights. Every detail of these machines has been carefully crafted to guarantee precision cutting tolerances during the cutting process, which is why all of these machines are especially suited for fabricating vessels as well as for offshore production. Expect thick wall accuracy and perfect-fit technology delivering exceptionally round holes, as well as the elimination of layout time. Plus, count on holes being easily located, positioned and cut with unparalleled accuracy and at maximum speeds for all ranges of walled thicknesses. Pressure vessels that used to take as much as ten hours to prepare and cut now take about an hour. These machines are designed to profile complex beveled edges and 3D profiles made from steel. Combining robotics, a patented biaxial cutting head and proprietary software, these Pipe Cutting machines enable users to cut angles from plus 70 deg to minus 70 deg, a capability that assures optimal weld preparation for precision part alignment, which in turn reduces welding and fitting costs by over 30 percent.

HGG Profiling Equipment, 3977 Rivendale Drive, Medina, OH 44256, 330-461-6855, jt@hgg-group.com, www.hgg-group.com.