How to Increase Productivity and Efficiency in Production Stamping

The Fibro Electronic Tapping Unit and the Wireless Pressure Monitoring from Fibro enables production stampers to add value, increase throughput and improve operational efficiency.

Posted: September 13, 2019

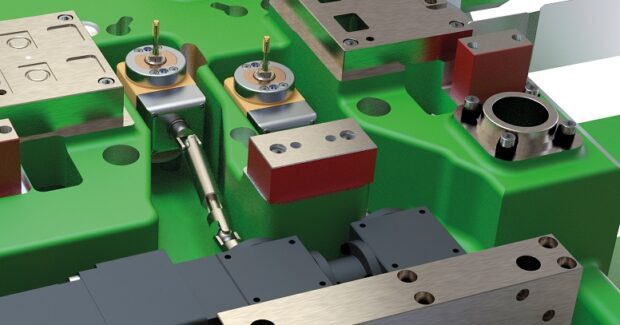

The Fibro Electronic Tapping Unit (FETU) from Fibro Inc. (Rockford, IL) incorporates the latest advances in servo technology and process control, a thread range of M0.8 to M24, and production speeds exceeding 140 spm for production stampers to increase productivity and efficiency. Whether mounted directly in the production stamping tool or as a value-added offline work station, the FETU has the flexibility to optimize stamping throughput by offering the following advantages:

- Flexibility – The electronic tapping heads can be used in a wide variety of presses, dies and automatic punching machines due to the independent drive and versatile control unit.

- Quality – The thread tapping unit produces high quality threads using its auto-teach function. The system automatically monitors and adjusts the process parameters as needed to ensure the critical thread tolerances are maintained. All data sets are recorded and can be read out or summarized in report form.

- Cost effective – Long tool service life, faster processing times and it can utilize the same drive and control components for multiple thread sizes.

- Standard and Custom Tapping Heads – Application engineers work with customers to select the optimal tapping head for their specific requirements.

- Internal Lubrication – Minimizes maintenance and production set-up requirements.

The primary components of the FETU are:

- Control Unit – The controls and the servo regulator for the drives are housed within the Control Unit which can regulate up to six independent drives. Ten programs per unit allow for unrestricted programming of the process parameters as well as the data storage for operational reporting.

- Tapping Head – Multiple Standard Tapping Heads from M0.8 to M24 with custom heads available, internal lubrication is available on some models.

- Drive – Synchronous servomotor capable of single or multi-use applications. The drives function independent of the press stroke or motion.

- Drive Shaft – Optional for connecting tapping heads in hard-to-wreach locations.

The FETU offers quality and flexibility in a cost effective package to the production stamper looking to add value, increase throughput and improve operational efficiency. Also on display will be their Wireless Pressure Monitoring (WPM) system of nitrogen gas springs and systems. The use of nitrogen gas springs in metal stamping dies has grown exponentially since being introduced into the market 35 years ago. Over that period of time, the quality and service life of nitrogen gas springs has steadily improved, but one thing has not changed: all nitrogen gas springs and systems will eventually leak. So the question for the production stamper is: When a nitrogen leak occurs, how much scrap will be produced before the leak is detected? There are different methods to monitor the pressure of a nitrogen gas spring or systems:

- An analog gauge can be used allowing an operator to check the pressure prior to production, but there is still no warning when a leak occurs. This also requires hose and fitting connections, which mean more potential leak points.

- An electrical means of monitoring the pressure can be used. These systems can be wired into the press controls to stop the production should a leak occur. This is an improvement over a gauge, but also limited in use because the hoses and wires required restrict use in upper dies and/or where automation interference may occur.

- WPM requires no additional hose or wire connections, provides Bluetooth™ 4.0 communication, 24-hour monitoring and documentation and early warning of nitrogen pressure loss to prevent downtime and secondary failures and optimize maintenance intervals.

The four primary components of the WPM system are:

- Sensors – battery operated, connect to a nitrogen gas spring or system, transmit pressure and temperature data to the die mounted Data Part via Bluetooth 4.0.

- Data Part – battery operated, stores all die specific data, including die number, sensor list and location – can receive data from up to 128 sensors – communicates with the Gateway (or customer supplied read out device such as PC).

- Gateway – 24VDC, mounted to the press, connects to press controls via digital I/O, relay contacts, Ethernet, etc. – communicates with the press to signal a warning and/or full stop should the sensors detect a nitrogen pressure loss or spike in operating temperature.

- Proprietary Software and Bluetooth 4.0 Receiver – enables the user to configure the sensors, Data Part and Gateway for the specific nitrogen system requirements of a particular die. Two pressure set points per sensor. Early detection for scrap free production. Targeted maintenance intervals – service the nitrogen system before major failure. Ease of installation – no wires or hoses required within the die. Documentation – record pressure and temperature data for evaluation.

The Wireless Pressure Monitoring system provides zero defects and scrap due to the loss of nitrogen gas spring or system pressure to the production stamper.

Fibro Inc., 139 Harrison Ave., Rockford, IL, 61104, 815-229-1300, Fax: 815-229-1303, info@fibroinc.com, www.fibroinc.com.