Laser Cladding Services

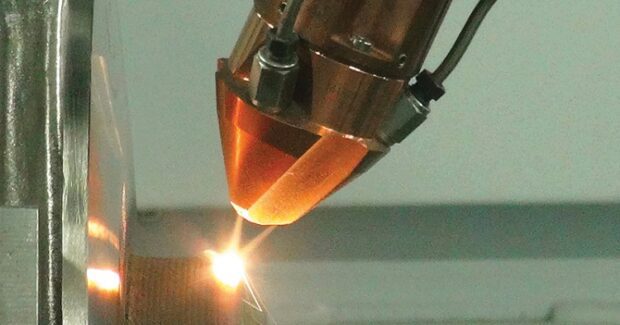

For repairing damaged components and enhancing surface protection properties for better wear or corrosion resistance, laser cladding services from Alabama Laser use lasers to deposit a layer of material onto a substrate utilizing either powder or wire.

Posted: September 23, 2019

In Booth B-34034, Alabama Laser (Munford, AL) features laser cladding services that use lasers to deposit a layer of material onto a substrate utilizing either powder or wire. This process is used for repairing damaged components and enhancing surface protection properties for better wear or corrosion resistance. Laser cladding offers improved performance over conventional surface coating techniques, including:

- Production repeatability with stable production rates.

- Minimum dilution with consistent chemistry throughout the clad.

- Minimum component distortion and minimum heat affected zone.

- Metallurgically bonded cladding with minimal porosity.

Alabama Laser, 152 Metal Samples Road, Munford, AL 36268, 256-358-9055, als@alspi.com, www.alabamalaser.com, www.alspi.com/lasercladding.htm.