Robotic Grippers for Efficient Tending of Metal Fabrication Operations

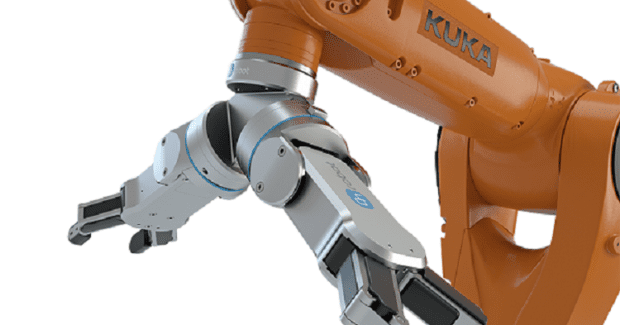

The RG2 Collaborative Gripper and the VG10 dual-zone electrical vacuum gripper from OnRobot provide dual grip capabilities, flexibility and more to optimize handling and cut machine tending time.

Posted: September 5, 2019

OnRobot US Inc. (Irving, TX) offers two grippers for metal fabricating applications. First, the RG2 Collaborative Gripper is end-of-arm tooling designed for a seamless integration with collaborative robots and light industrial robots. On display will be the RG2 Dual Gripper demonstrating optimized handling that can cut machine tending time in half by handling both raw stock and finished product in same cycle. A wide stroke and accurate adjustable gripping force enable the RG2 to handle a variety of objects and sizes. This gripper requires no external cables, external power supply or any additional integration packages. Other features include:

- Payload up to 2 kg.

- Adjustable gripping stroke from 0 to 110 mm.

- Adjustable gripping force from 3 N to 40 N.

- Gripping force accuracy better than ±2 N.

The VG10 Gripper is the world’s first dual-zone electrical vacuum gripper. It is specially designed to allow vacuum gripping without the need for external air supply. Its flexible arms and adjustable vacuum enable this gripper to handle a variety of object in many different sizes. The VG10 comes with dual grip functionality, a tool changer, a variety of typical vacuum cups, and works straight out of the box in less than 30 minutes. Both the VG10 and the RG2 Grippers come with a single mounting bracket and works on robots by Universal Robots, KUKA, Kawasaki, FANUC, Techman, Doosan, NACHI and Yaskawa.

OnRobot US Inc., 222 Las Colinas Boulevard W, Suite 854E, Irving, TX 75039, 469-442-9370, www.onrobot.com.