Tube Processing for High-Tech Medical Applications

Advanced forming and bending machines from transfluid deliver accurate tube processing of high and ultra-high strength materials.

Posted: September 9, 2019

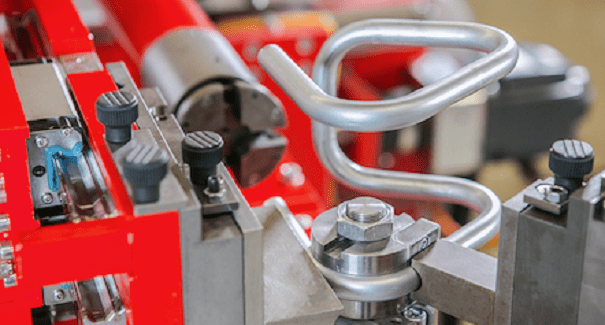

In Booth D-46577, tube processing machines from transfluid® Maschinenbau GmbH (Schmallenberg, Germany) can make parts used in surgical instrument technology, emergency care, sterilization autoclaves and other medical equipment. A crucial challenge for these machines is forming tubes with very thin walls made of special materials, including high and ultra-high strength materials such as titanium and stainless steel that is used in microsurgery or endoscopy. These machines produce highly precise symmetrical and asymmetrical axial forms when forming axially or with the rolling method. “Roll forming is very important because it can be used in a very effective way and independent of the tools used,” said Stefanie Flaeper, the director of transfluid. “These machines reduce the tubes partially or over a long distance by using so-called ‘incremental forming’ that opens up new possibilities in many cases. Both methods – axial and rolling – offer outstanding precision when processing tubes with a relatively small outer diameter between less than 1 mm and up to 12 mm.”

Tubes with larger diameters are often produced in larger numbers for use in medical aids that improve the recovery and quality of life of patients. The same demands apply in the care and rehabilitation fields, but with different prerequisites. Here the focus is on creating options for processing tubes and profiles used in the frames of beds, auxiliary and lifting devices, examination devices, personalized aids or devices commonly used in the care sector. For this large variety of applications, transfluid offers a selection of machines that bend the pre-cut tube and form the ends. These systems can be connected to a network, operate as stand-alone and be equipped with relevant automation, or be set up as a completely automated process. The CAD data is loaded into the system online, making it possible to have highly flexible manufacturing when necessary.

Different materials are processed in all areas of medical care. Light, high-strength materials are preferred in emergency care and in rehabilitation, where the production of wheelchairs is tailored to the person and their needs from a selection of sizes, colors or additional functions. To achieve the best possible tube processing, the counterclockwise and clockwise bending machine t bend 630 CNC R-L can be used. Its fast, flexible changing of tools makes individually adjusted bending possible and guarantees high-quality bending with small bending radii. All transfluid machines work manually or fully automatic. Integration of the manual systems into a production cell is also possible.

transfluid Maschinenbau GmbH, Hünegräben 20-22, 57392 Schmallenberg, Germany, +49 2972 97150, www.transfluid.de.