Arc Welding Takes Center Stage

Yaskawa Motoman introduces the AR3120 robot, ArcWorld 50 series workcells with YRC1000 controller, and a Universal Weldcom Interface pendant application that can fully utilize advanced capabilities on select Miller, Lincoln Electric and Fronius digital welding power supplies.

Posted: October 24, 2019

Offering an extra-long wrist range for improved application flexibility, the new extended reach six-axis AR3120 robot from Yaskawa Motoman (Miamisburg, OH) achieves unrivaled arc welding performance. Featuring an expansive 3,124 mm horizontal reach and a 5,622 mm vertical reach, the AR3120 is the longest reach, standard arc welding robot available. This powerful and efficient arc welding robot optimizes weld quality and product throughput. With the highest payload, fastest axis speeds and top wrist allowable moment in its class, it is ideal for use on agriculture equipment, construction machinery or automotive frames. Perfectly suited for use in high-density layouts with multiple robots working in close proximity, the AR3120 robot has a slim profile that features a streamlined arm design for reduced interference, facilitating access to parts in tight spaces. Its 20 kg payload capacity supports a wide range of motorized torches and sensors, and a symmetric wrist profile with impressive range provides equal torch access to both side of the part. An optimized feeder mounting area on the arm reduces equipment interference.

Thru-arm routing for cabling, hoses and sensor wires is provided by the large 50 mm thru-hole, allowing ample space to minimize cable snagging and wear. Similarly, the minimal protrusion from the U-axis, along with the internal S-axis routing, prolong cable life and maximize part access. Installation is quick and efficient. A new robot harness design improves diagnostics and maintenance, and a single cable connects the manipulator to the controller, resulting in easy setup and reduced expenses. The AR3120 robot can be floor-, wall-, tilt- or ceiling-mounted, and it is controlled by a high-performance YRC1000 controller that is built to a global standard and does not require a transformer for input voltages ranging from 380VAC to 480VAC. With a highly-compact cabinet (598 mm W x 490 mm H x 427 mm D), the YRC1000 utilizes a lightweight teach pendant with intuitive programming.

Yaskawa Motoman also offers affordable, extremely compact ArcWorld® 50 series workcells that are built for demanding production environments as wire-to-weld solutions pre-assembled on a common base. Available in single or dual station configurations, these workcells are equipped with all the automation needed for arc welding. Each ArcWorld 50 model features an AR1440 welding robot, compact YRC1000 controller with menu-driven arc welding application software, integrated welding package, operator station, one or two powered roll-up doors, and a total safety environment. Fixed tooling tables, or one or two MH185 headstocks offer the flexibility required for high- or low-mix production for small- to medium-sized parts. Several model configurations are available, including:

- Single station with integrated tooling riser (ArcWorld 50).

- Single station with servo-driven MH185 headstock (ArcWorld 50S).

- Dual station with fixed tooling (ArcWorld 52).

- Dual station with two MH185 headstocks (ArcWorld 52S)

A single large tabletop or two smaller tabletops are available as options. The high-speed, six-axis AR1440 robot has a 12 kg payload capacity to support a wide variety of torches and sensors. Its powerful, compact YRC1000 robot controller features patented coordinated motion between devices. The MH185 headstock positioner has a 185 kg payload overhung 250 mm from the faceplate. ArcWorld 50 workcells include an intuitive digital welding interface for Miller, Lincoln or Fronius power sources, plus required torch, wire feeder and sensor options. Advanced welding functions, such as weld inspection and process monitoring, can be included as an option. Standard EtherNet/IP connectivity is used to connect most peripheral devices and includes a utility to set-up and troubleshoot connections to the robot.

Each workcell features a total safety environment compliant with ANSI/RIA R15.06-2012 (and other international standards). Powered roll-up doors improve ergonomics and are interlocked with robot operation to safeguard the operator during part load/unload. Safety features include a single point of operator control, dual-channel light curtains and E-stop functionality, safety interlocked gates, integrated speed monitoring and manual brake release for the robot. A host of pre-engineered, value-added options are available, including isolation transformers, second enabling switch, tip change box, bulk wire delivery, low wire sensor, gas flow sensor, exhaust hood and a stack light. ArcWorld 50 models are easy to set up and relocate. The space-saving workcell design has a 4,570 mm x 2,285 mm (15 ft x 7.5 ft) footprint and fits in a standard 110 in trailer. The robot, positioner and safety fence all ship on a common platform, reducing installation and setup time. The controller and power source are shipped attached to the cell base and can be separated for maintenance.

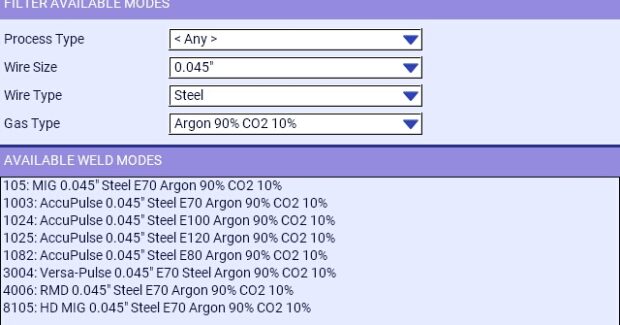

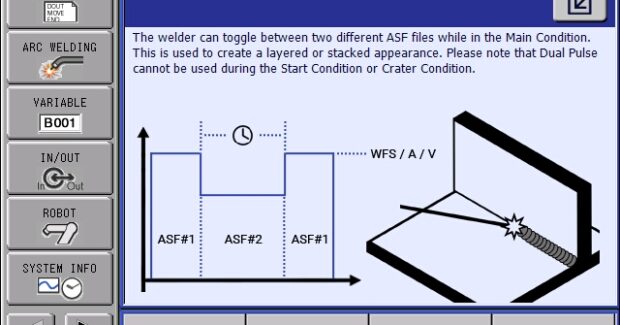

Yaskawa Motoman also offers the Universal Weldcom Interface (UWI), a new easy-to-use pendant application that enables full utilization of the advanced capabilities on select Miller and Lincoln Electric digital welding power supplies. UWI enables easy control of any weld process or parameter, including voltage, amperage and wire feed speed through a common user interface for either brand. Highly functional, the UWI can filter weld modes based on process type, wire size, wire type and gas type. Up to 16 unique processes from the power source library can be defined for easy access within the interface, and up to 1,000 custom arc files with specific processes and parameters are available for use in motion programming. Up to six weld process parameters in a weld sequence – such as Pre-Flow, Start, Main, Crater and Finish Condition – can easily be set. Standard functions – including Arc-Retry, Arc Monitor Data Enable, Re-Start and Weld Line Shift – are conveniently utilized. A new Dual Pulse function allows alternating between MIG weld parameters and settings for aesthetically pleasing TIG-like cosmetics.

Weld settings on the UWI use terminology that matches the user’s preferred power source. Standard ARCON commands are used, eliminating the need for complicated macro jobs. Programming with arc file interface or inline instructions is supported. Easy access to graphical help screens explains terminology and functions. The Universal Weldcom Interface is fully compatible with arc welding performance tracking features native to the power source. Live weld status is presented on the IF Panel display or Graphic Arc Monitor. Weld data can be exported for use in PLCs and part quality serialization. Arc Monitor results from Miller Insight Centerpoint™ or Lincoln CheckPoint Production Monitoring can be used for alarms or reported to PLCs. Hardware communication for diagnostics is also monitored and logged. UWI can be used on up to four AR-Series arc welding robots with YRC1000 controller (YAS2.81.00-00 firmware or higher). It is compatible with the Miller Auto-Continuum™ 350 or 500, or the Lincoln Power Wave with ArcLink XT. A simplified networking utility enables easy setup between the robots and the welders. Additional features and global power source compatibility are planned in the future.

Yaskawa America, Inc., Motoman Robotics, 100 Automation Way, Miamisburg, OH 45342, 937-847-6200, Fax: 937-847-3288, www.motoman.com.