Breakthrough Technology: Handheld LIBS for Fabricators

Almost every major pipeline owner/operator now either uses a portable LIBS device for verifying their materials or requires their non-destructive testing contractors to use it. Almost every major refinery uses one for carbon testing, as do the inspection companies that support their PMI/NDT programs. Here’s why.

Posted: October 7, 2019

Metal fabricators are seeing increased requirements for verifying alloy grade and chemistry for their steel and alloy product. Alloy verification, also called positive material identification (PMI), originated in the oil/gas industry and was driven largely by API’s Recommended Practice 578. PMI requirements in recent years have expanded into midstream oil and gas, power industries, aerospace and other heavy transportation. Now, the Department of Transportation is about to publish the “PHMSA Mega Rule” requiring, among other things, testing of transmission pipeline materials for carbon, manganese content and carbon equivalents (CE). For fabricators handling alloyed materials that do NOT require carbon content verification or CE, PMI has been a relatively straightforward task. Handheld X-ray guns have been in use for more than 30 years to analyze low alloy steels, stainless and high-temperature alloys. They are easy to use, and modern guns only take a few seconds for most analysis. The challenge has been performing PMI on carbon steels and L-grade and H-grade stainless.

However, there are important differences between using the handheld XRF and LIBS: namely, the preparation and operator training. Carbon testing is significantly more difficult than the “point and shoot” simplicity of XRF. Carbon is ubiquitous; any carbon residue from soil, dust, oils from skin, etc. will create false high-test results. It is critical that operators receive solid training and understand the importance of proper sample preparation. For this reason, SciAps offers lifelong, free training for as long as the company owns the LIBS.

THE CARBON OLD GUARD: SPARK OES

Until 2017, spark OES had been the only technique for in-field carbon analysis. Mobile spark OES is still a cart-mounted instrument package consisting of a handheld probe, spectrometer and electronics box, and a 50+ lb tank of compressed argon gas. Many fabricators have avoided purchasing spark OES systems for carbon analysis by opting to trust material test reports (MTRs) or have third-party testing companies perform the carbon analysis. That’s because spark OES units are not easily portable in real-world scenarios, and stocking and transporting the high-pressure tanks of argon gas is challenging. Many operations require moving the spark OES unit around shop floors, onto racks or stacks of materials, up towers or stairs, or, in the most extreme example, lowered and raised by a lift into/out of a ditch for pipeline testing. In many cases, prior to moving the OES, the argon flow is shut off. Once the analyzer is relocated, the argon is turned back on, the system re-purged, and the analyzer recalibrated. Users say the re-purging and recalibration process requires about 45 minutes, reducing productivity.

Unless operators only test at a workstation, LIBS is always the better choice. LIBS is easier to ship to different locations than spark OES. No additional work or recalibration necessary, allowing testing companies to maximize the LIBS assets. No matter where the job is, the LIBS will have the right software and calibrations. The new LIBS technology is truly handheld. Climbing, crawling, and getting into and out of pipeline ditches is easy. The re-purging process takes a few seconds, and there’s no recalibration afterwards. Operators simply move from location to location and continue testing.

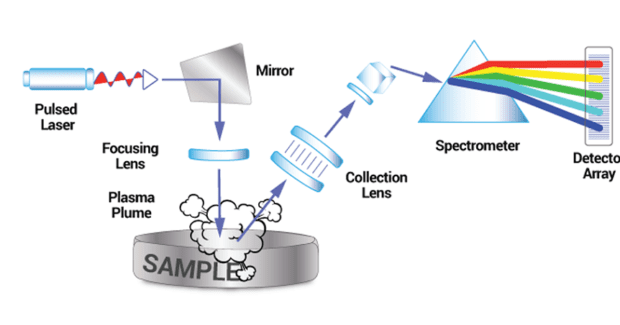

WHAT IS LIBS, AND HOW DOES IT WORK?

LIBS is an OES method like spark OES, but the weighty high-voltage AC spark source is replaced by a small, battery-powered pulsed laser (a box about 1.5 in x 1.5 in x 1 in). The laser burns into the metal instead of the electric spark, producing the light that is analyzed by the on-board spectrometer. Two significant technical breakthroughs made carbon measurements possible with a handheld.

- First, the laser was miniaturized, making a small, battery-operable unit that could vaporize high-temperature metals. The key is the time characteristics of the pulsed laser. The energy in each laser pulse is about 6 MJ. If ran continuously, it would be MW of power, clearly not enough to vaporize metal. Instead, the laser energy pulse is about 1 ns (one-billionth of a second) in duration. This means the instantaneous power delivered to the metal is 6 MJ divided by 1 x 10-9 seconds, thus about 6 MW. Very high power, in a short amount of time, is enough to vaporize the metal and create the necessary plasma for spectroscopic analysis.

- Second, the rate of argon consumption has been reduced by more than a factor of 1,000 compared to spark OES. The key here is the small diameter laser beam. The beam is < 100 um diameter, so the LIBS device requires only a few cc’s of purge volume and the volume requires only a few seconds purging during pre-burn. Between tests, the argon flow stops. The small volume coupled with starting/stopping the purge reduced the need for argon supply to a tiny canister (1 in diameter by about 2½ in long) in the handle instead of the 50 lb external tank. The canister delivers 600 burns. When averaging three burns per site, each canister provides analysis of about 200 materials.

TECHNOLOGY ADOPTION

As a Boston-based instrumentation company specializing in portable analytical instruments and technology development, we are now completing our third year of commercial shipments of carbon testing units with the SciAps Z analyzer. Handheld LIBS is now included in API Recommended Practice (RP) 578 Third Edition for carbon testing. On the pipeline side, at least four independent studies have proven that the SciAps Z performs equivalent or superior to spark OES technology for carbon and CE. Almost every major pipeline owner/operator either uses a Z for their materials or requires their non-destructive testing contractors to use it. In fact, the SciAps Pipeline App was born when the largest owner/operator tested and accepted the Z for carbon and CE in pipeline materials, with a specific testing protocol included in the app. On the downstream side, almost every major refinery uses the Z for carbon testing, as do the inspection companies that support their PMI/NDT programs. An ASTM Method is in process and expected to be completed in 2020.