How to Improve Pick-and-Place Small Part Handling

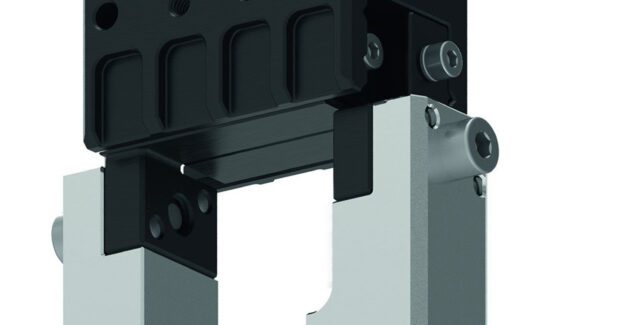

The lightweight EGB four-stage mechatronic gripper from SCHUNK swiftly and accurately picks and places even deformation-sensitive parts.

Posted: October 18, 2019

With its ability to vary finger position and gripping force during each cycle, the EGB 24V gripper from SCHUNK, Inc. (Morrisville, NC) swiftly picks and places even deformation-sensitive parts. It maintains consistent force and speed over the entire stroke within permissible finger length via software that automatically adjusts force depending on the part and an integrated measuring system that constantly monitors finger position. Intermediate positions or varying workpiece sizes can be monitored at any time. In the version with IO-Link, the gripper satisfies the IO-Link Class B standard suitable for increased power consumption and can be directly connected with an IO-Link Class B master. Integrated diagnosis tool monitors voltage, current, temperature, and condition and transmits errors automatically to the control system. Systems operators can also store maintenance intervals for the system on the tool.

Like its predecessor, the pneumatic MPG-plus, the EGP takes screws on the side or at the base to increase work envelope flexibility. It will initially be available in sizes 40, 60, and 64 with a finger stroke of 6 mm/ 8 mm/ 10 mm and maximum gripping forces of 140 N/ 210 N/ 300 N. Repeat accuracy during operation is 0.02 mm with 0.1 mm to 0.2 mm during finger positioning, depending on whether the finger position is reached from one or two directions. The EGB handles parts up to 0.7 kg/ 1.05 kg/ 1.25 kg and is also available with actuation via digital I/O.

SCHUNK, Inc., 211 Kitty Hawk Drive, Morrisville, NC 27560, 800-772-4865, Fax: 919-572-2818, www.schunk.com.