Improve Material Flow from Work Cell to Work Cell

Versatile Shuttle / Transfer Carts from Verti-Lift integrate portability, lifting, and conveying when material flow from work cell to work cell is required.

Posted: October 31, 2019

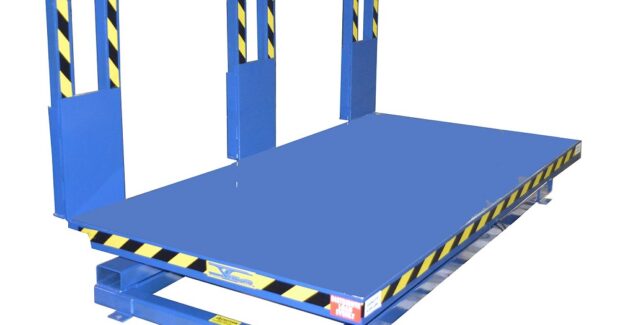

Versatile Shuttle / Transfer Carts from Verti-Lift, Inc. (Louisville, KY) integrate portability, lifting, and conveying. With the option of V-Grove casters or Flanged casters (for plant pedestrian traffic areas that will not allow obstruction), portability allows product movement between multiple work cells or processes. The integrated scissor lift allows for elevation changes while the conveyor provides the ability to transfer product between multiple work cells or processes. Whether the application requires sheet handling (steel plate, wood, or corrugated), product handling (electrical enclosures, lockers or a wide range of oversized products), or unit load handling (pallets, totes, or containers), the integration of portability, lifting, and conveying make the Shuttle / Transfer Cart an ideal solution when material flow from work cell to work cell is required.

The company works closely with distributors and system integrators to design, build, and integrate their material handling equipment into new or existing facilities and production lines. All Shuttle / Transfer Carts feature easily accessible internal power units, heavy duty cylinders, hand or foot controls, heavy duty tubular frames, heavy duty hydraulic cylinders, and lifetime lubricated bearings to ensure a long service life with no maintenance.

Verti-Lift also offers VL Hydraulic Upenders with a V-cradle design that are ideal for ergonomic positioning of rolls of steel, paper rolls, coils or spools, tubular tanks and other cylindrical products. With a 6,000 lb capacity, these positioning devices have enough power to re-position heavy loads, while the V-cradle keeps the load intact during movement. All VL Hydraulic Upenders feature 0 to 90 deg tilt angle, hold-down tabs on all four corners, heavy-duty cylinders for maximum service life, 110V AC, single-phase motor with 15 amp draw, and standard hand controls for lowering/raising tilt. Optional accessories include foot control, oversized platforms to suit specific material handling requirements, roller conveyors, accordion skirts, remote power units and PLC control. In addition to coil and roll handling, these Hydraulic Upenders are ideal for the safe and repositioning of pallets loads and odd shaped objects.

Verti-Lift also offers versatile Floor Level 90 Degree Tilt Tables with Removable Forks for any manufacturing or assembly application where the process requires work in the horizontal and vertical positions. With the flexibility of removable forks while in the horizontal position and a range of 0 to 90 deg, workers are allowed 360 deg access to the product while in the horizontal position, while the vertical position allows access to manufacturing and assembly of difficult-to-reach areas in the vertical position. Removable forks allow pallet jack or fork truck loading or unloading in the vertical position. Forks are ideal for applications where product (feet or wheels) need to be installed at the base of the product. Assembly can be accomplished in the horizontal position, the product rotated 90 deg, and the product set on the floor where it can simply roll to the next process or be moved by pallet jack in areas where fork truck space is limited. These Floor level 90 Degree Tilt Tables with Removable Forks are ideal for many applications, including panel build, furniture manufacturing, locker or metal enclosure manufacturing and assembly, corrugated, wood, or sheet handling.

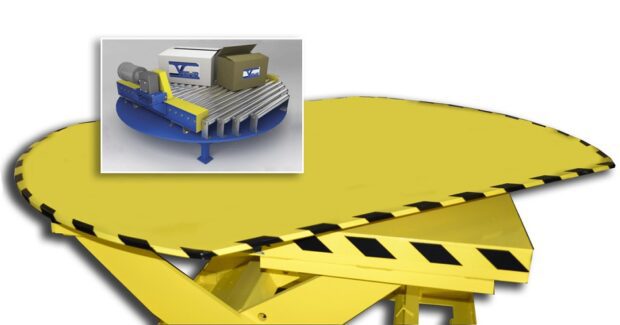

Verti-Lift also offers manual turntables that enhance ergonomics and productivity by eliminating the need to walk around or reach across loads, especially during pallet loading or unloading. These heavy-duty, low-profile turntables have a ½ in thick steel top turntable and boast a 4,000 lb capacity. Optional conveyor-topped models are available for in-process workstations. Seven platform sizes, both square or round, from 24 in x 24 in up to 60 in x 60 in suit most applications. Custom shapes and sizes are available. Detents can be added at 90 deg and 180 deg to further enhance operator efficiency. Lifetime lubricated kingpin bearings ensure a long service life with no maintenance. These manual turntables can be floor mounted, stand-mounted or on hydraulic or pneumatic scissor lifts, making them ideal for palletizing, de-palletizing, work station assembly and manufacturing of all kinds in all industries.

Verti-Lift, Inc., 5559 National Turnpike, Louisville, KY 40214, 502-361-0180, sales@verti-lift.com, www.verti-lift.com.