Ingersoll Awarded Contract for Giant Telescope

The $135 million Giant Magellan Telescope structure contract will require nine years to complete.

Posted: October 31, 2019

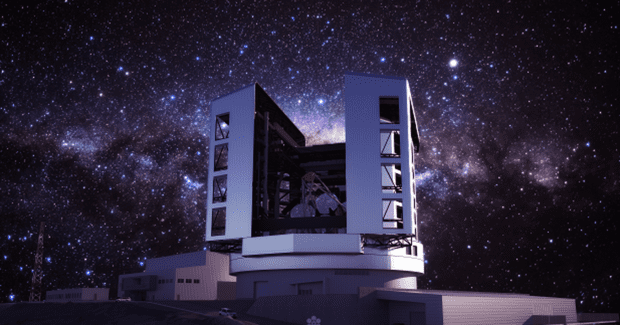

Camozzi Group (Brescia, Italy), through their fully-owned subsidiary Ingersoll Machine Tools, Inc. (Rockford, IL), entered into an agreement in conjunction with MT Mechatronics GmbH (Mainz, Germany) – with GMTO (Vallenar, Chile), the organization managing the development of the Giant Magellan Telescope (GMT) on behalf of their U.S. and international founders, to build the telescope’s steel precision structure. The GMT is an 80 ft diameter next-generation giant optical-infrared observatory that will explore the frontiers of astronomy, seeking forms of life beyond our solar system and capable of changing the history of space exploration.

The $135 million telescope structure contract will require nine years of effort by a large workforce of engineers, designers, metalworkers, and machinists. “Manufacturing the telescope structure is one of the biggest steps we will take on our journey to building the Giant Magellan Telescope,” said Dr. Robert N. Shelton, the president of GMTO. “Following a two-year global competition, we selected Ingersoll and MT Mechatronics for their commitment to quality, extensive experience with astronomical telescopes, and abilities to manufacture complex precision structures,” added Dr. James Fanson, a GMTO project manager.

Ingersoll, together with MT Mechatronics, will design and manufacture the 1,300 ton precision mechanism known as the “telescope structure” that holds the telescope’s optics used to smoothly track celestial targets as they move across the sky. The telescope will be designed by MT Mechatronics and manufactured, assembled, and tested by Ingersoll before being shipped to and installed at the GMT observatory site high in the remote Chilean Andes. The structure of the telescope will hold the seven giant mirrors of the GMT in position as they bring the light of distant stars and galaxies into focus so that they can be analyzed by the scientific instrumentation built into the telescope. The mirrors, the largest in the world, have been produced by the Richard F. Caris Mirror Lab of the University of Arizona. The structure is expected to be delivered to Chile at the end of 2025 and be ready to accept the mirrors in 2028.

The structure of the telescope, complete with mirrors and all instrumentation, will weigh 2,100 tons and will float on a 50 microns thick (.002 in) oil film that will ensure frictionless movement to offset the earth’s rotation and follow the celestial bodies in their paths across the sky. This “hydrostatic” technology was patented several years ago by INNSE, a Camozzi Group company renowned throughout the world for this technology. With its unique design, the GMT will have a resolving power 10X greater than the Hubble Space Telescope in the infra-red section of the spectrum. “It will be a special day when the GMT structure is completed and placed in service in Chile as part of one of the most complicated and fascinating projects that the world scientific community has ever undertaken,” noted Chip Storie, the chief executive officer of Ingersoll Machine Tools.

The GMT is poised to enable breakthrough discoveries in cosmology, the study of black holes, dark matter, dark energy, and the search for life beyond our solar system. The telescope’s primary mirror combines seven 27 ft diameter circular segments to form an effective aperture 24.5 m in diameter. The GMT will be located at the Las Campanas Observatory in Chile’s Atacama Desert and the project is the work of a distinguished international consortium of leading universities and science institutions. Funding for the project comes from the partner institutions, governments, and private donors.

https://en.machinetools.camozzi.com