Now and Then: Affordable, Expandable Robotic Weld Cell Automation

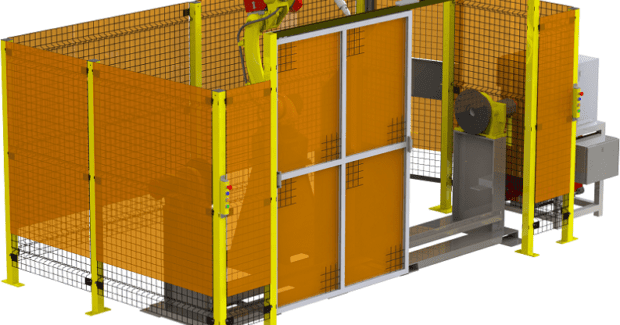

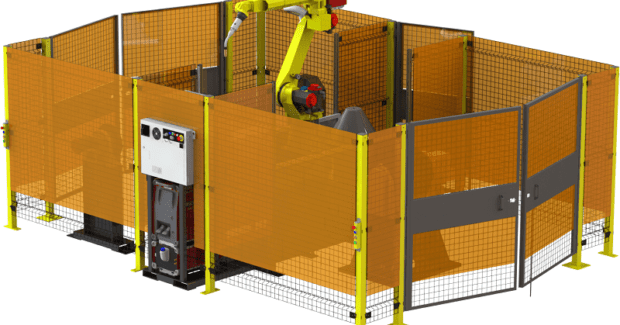

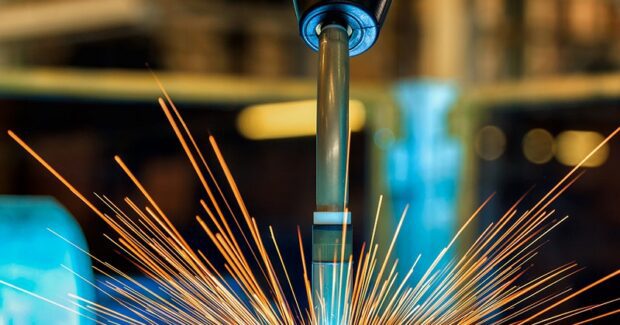

FASWeld Standard Robotic Weld Cells from Pre‐Tec allow shops to afford automation for the first time and then economically expand their robotic automation capabilities as their business needs change.

Posted: October 22, 2019

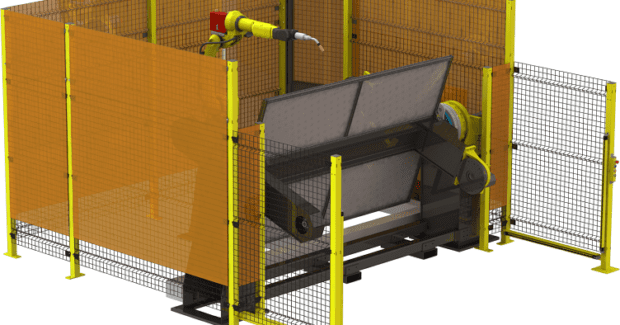

Unique FASWeld Standard Robotic Weld Cells from Pre‐Tec, a division of Willamette Valley Company LLC (Eugene, OR) are built using the highest quality industrial components. Each weld cell configuration is designed both for shops turning to automation for the first time and users looking to expand their robotic automation capabilities. A small footprint utilizing single‐piece platforms allows for rapid delivery and installation time through pre‐engineered systems that are affordable and simple to use. These cells enhance load and unload times through dual‐zone systems with room for customization as business needs change or expand. Each weld cell configuration is planned out based on user needs, from a simple flat table dual‐zone approach up to high production systems using servo‐controlled positioners. These systems can be provided as base models that are ready to be tooled and programmed by the user, or with part tooling, process development, and specific programming handled by the Pre‐Tec automation team.

Each weld cell configuration offers forklift pockets for quick transport within the facility, with leveling functions to ensure accuracy. Safety is at the forefront, with the presence of modular fencing, welding flash curtains, push-button operator controls and service access doors. “These affordable, expandable and easy‐to‐use robotic weld cell systems enhance the capabilities of shops when they first turn to automation and beyond,” said Stan Reynolds, the general manager of Pre-Tec. “Our customer base frequently looks to improve their manufacturing operations through automation, and FASWeld Standard Robotic Weld Cells allow them to do just that, while offering opportunities for growth as their business needs change.”

Pre‐Tec Division of Willamette Valley Company LLC, 990 Owen Loop North, PO Box 2280, Eugene, OR 97402, 541-484-2368, Fax: 541-343-2967, pre-tec@pre-tec.com, www.pre‐tec.com.