Sawing Starts with the Material

All materials present unique cutting issues. For the best sawing results, you must understand how material characteristics and sizes affect the cut to achieve the longest band saw blade life and production results.

Posted: October 8, 2019

All materials present unique cutting issues. Understanding the material characteristics before starting to cut presents the best opportunity to achieve the longest band saw blade life and production results. This article presents some general rules of thumb.

SOFT MATERIALS

Soft materials typically include carbon steels, aluminum, coppers etc. In some cases, soft materials can be as difficult to cut as hard materials. Soft materials tend to load the tooth gullets, resulting in premature wear and, in a worst case scenario, can even lead to tooth strippage. When the tooth gullets are filled, only the very tip of the tooth is doing any cutting. This can cause chip loading in the gullets and excessive forces on each tooth. The basic rule of thumb for tooth selection on any given material is to have no fewer than three teeth and no more than ten-to-14 teeth in the material at all times. Typically this allows the teeth to grab a chip and release it before the gullets are full. As soft material tends to load quicker, it is imperative to stay away from a blade with a fine pitch. Generally speaking, in most cases and dependent upon the specific soft material, it is better to select a coarser blade pitch versus a finer one.

HARD MATERIALS

Hard materials, such as Inconels, Monels, Hastalloys etc., present a different set of problems. Based on the cutting properties of these materials, it is very unlikely that the gullets will fill, so blade selection should reflect this characteristic. The teeth have a much more difficult time of engaging the material and typically pull a much thinner chip. This will allow selecting a blade that follows the higher end of the rule of thumb because more teeth will be engaged in the cut than would be possible when sawing soft material. For example, cutting 3 in aluminum using a 1.4/2 tooth pitch would stay within the criteria of having a minimum of three teeth in the material at all times. Based on the cutting characteristics of aluminum, this would typically work well. However, using the same blade to cut a similar size piece of Inconel 718 would cause premature blade failure due to the teeth being too coarse to engage and pull the necessary chip load. In this case, choosing a three-to-four tooth would likely be better because there would be more teeth engaged without concern of loading the gullets, resulting in optimal sawing productivity and maximum blade life.

SIZE DOES MATTER

The size of the material determines which tooth pitch to use. In general, the smaller the material/ part, the finer the tooth pitch should be. Alternatively, a coarser tooth pitch is desirable for larger parts. This is also true of materials that are bundled. While taking note of the individual size of the material bundled, also take into account the size of the bundle as a whole. Bundles can present problems when determining blade pitch and it is likely there will be no perfect solution. That said, arriving at a tooth pitch by determining what true material size the saw blade will be cutting helps determine the proper pitch.

APPLICATION CHALLENGES, SOLUTIONS

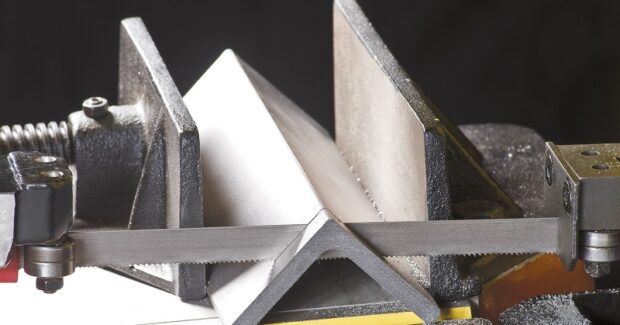

In one example when bundle-cutting angle iron, a customer based the tooth selection on the size of each angle and used a 10/14 pitch blade to cut a bundle that was approximately 10 in x 10 in. The 10/14 blade was much too fine a pitch to cut what was essentially a solid in the middle of the bundle. Our saw specialist recommended a three-to-four tooth, and both production and life increased dramatically. In another example, a customer had been successfully using our band saw blades for quite a while. However, they encountered a situation where blade life had decreased and they were not sure why. They contacted us and it was revealed they had been cutting carbon steels with a bi-metal blade, but had switched to Inconel when they had taken a new job. Not realizing the big difference that the much harder material made, they used the same blade and same speeds and feeds. By switching to a different blade, such as carbide tipped, and readjusting the speeds and feeds, cutting the Inconel is now successful.

There are many unique sawing applications where, when in doubt, it is best to consult with the band saw blade supplier to determine the optimal band saw blade to do the job at hand.