Welding Enclosures for Wire Arc Additive Manufacturing

Argweld Flexible Welding Enclosures from Huntingdon Fusion Techniques HFT keep an inert gas shield around titanium and other reactive alloy parts during wire arc additive manufacturing used in aerospace, medical and motorsport applications.

Posted: October 24, 2019

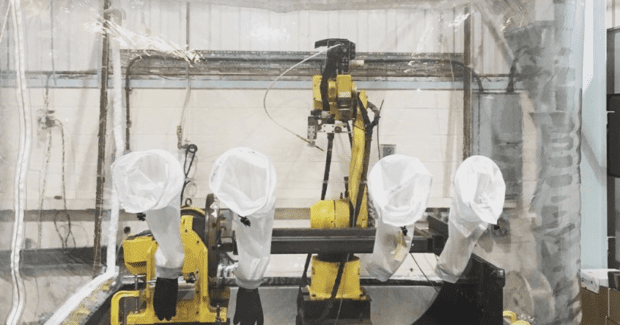

Wire arc additive manufacturing uses arc welding power sources and manipulators to build 3D shapes through arc deposition. This process commonly uses wire as a material source and follows a predetermined path to create the desired shape. This method of additive manufacturing is usually performed using robotic welding equipment. The use of Argweld® Flexible Welding Enclosures® from Huntingdon Fusion Techniques HFT® (Burry Port, UK) during the wire arc additive manufacturing process helps to keep an inert gas shield around titanium and other reactive alloy components with special protective enclosures. “We have built a large number of different shapes and sizes, mostly to customer specification,” said Georgia Gascoyne, the chief executive officer of HFT. “Each one has its own identity, with a variety of glove ports and dimensions. Some can accommodate a complete robot system internally. They are in use worldwide for applications in the aerospace, medical and motorsport sectors. Inert gas, such as argon, is used to fill the enclosure and expel the air until the oxygen content is below 50 parts per million (ppm). It is essential when producing metallic components from alloys of titanium, zirconium and other reactive materials that the welding zone is purged of oxygen to a level lower than 50 ppm.”

These Flexible Welding Enclosures provide a solution where a rigid chamber may not be economically viable or where space may be at a premium. “For many years the enormous cost of a metal enclosure prevented all but the major companies taking on work involving the fabrication of zirconium and titanium alloys,” noted Luke Keane, from Technical Support at HFT. “These enclosures came to the rescue.” The enclosures are manufactured with a number of glove ports. The upper half of the enclosure is made of optically clear, ultra-violet resistant, engineering-grade PVC that provides excellent vision. Transfer sleeves makes it possible to pass small parts in or out of the enclosure without affecting the purge quality. Operator comfort and ease of use with these enclosures, when compared with rigid chambers, is a big hit with welding personnel.

HFT COB USA, 6909 Vickie Circle, West Melbourne, FL 32904, 321-723-3200, Fax: 321-984-8455, general@cob-industries.com, www.huntingdonfusion.us.