What’s Hot in the World of Welding: (Part One)

Sailing on waves of innovation to meet demands for greater productivity, higher efficiency and improved quality, welding shops are using new equipment, tools and systems to address the skilled labor shortage, connect to the Smart Factory revolution and achieve leaner, more profitable operations.

Posted: October 29, 2019

Is any other industry as hot as welding? With new process technologies, new materials to join and be joined, rapidly increasing conventional welding process capabilities – the welding industry is sailing on waves of innovation to meet the demands for greater productivity, higher efficiency and improved quality as fabricators work to address the skilled labor shortage by connecting to the Smart Factory revolution to achieve leaner, more profitable operations. Here is some of the latest equipment, tools and systems that shops are using to weld jobs faster and learn how to effectively join new materials that have more sophisticated chemical composition with properties that provide better functionality and durability in general and heavy fabrication, construction, power generation, automotive, transportation and other applications:

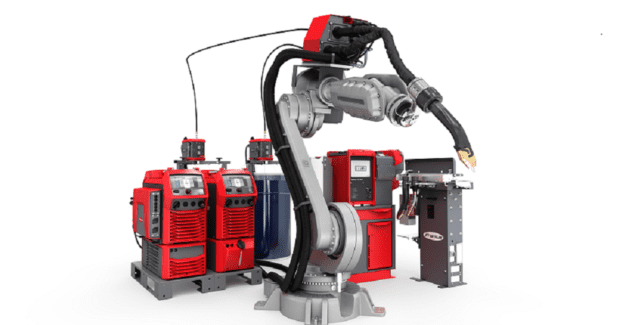

Welding Systems Reduce Costs in High Volume Operations or Jobsite Work

The TPS/i TWIN Push tandem welding system from Fronius is ideal for high-volume precision, while their TransSteel Series multi-process welding systems provide high-quality flexibility do a wide variety of different tasks.

Robotic Torch Reaming

The TCS-FP Torch Cleaning Station from Abicor Binzel integrates best-in-class reaming and wire cutting features with a motion-activated anti-spatter injector, future Fieldbus connectivity and a single point connection for all electrical wiring.

Ultralight Magnesium Alloys for Superior Welding

An affordable, high performance and sustainable alternative to aluminum, steel and titanium, ultralight ALLITE Super Magnesium alloys are specifically designed for superior welding, forging, strength and stability.

Advanced Spot Welding and Capacitive Discharge Power Supplies

The MacGregor DC2013-T resistance welding power supply from Amada Miyachi America combines touch panel-integrated database process control and monitoring with ultra-high duty output, while their compact CD-V capacitive discharge welders feature dual-pulse output.

Grinding and Mech Notching Wheels for Midstream Pipeline Construction

Tiger Pipeliner grinding wheels and Tiger Mech notching wheels from Weiler Abrasives were developed specifically for demanding pipeline applications with feedback from pipeline welders and helpers.

Breakthrough Versatility and Speed in Weld Inspection

The SURF-X Weld Array Probe set from Zetec combines +point coils to find indications in weld toes while array coils test the remaining weld and heat-affected zones, such as shipboard T and Butt welds.

Advanced MIG Gun Consumable System Maximizes Productivity and Weld Quality

AccuLock S Consumables from Bernard work together as a complete system, improving performance and minimizing – if not eliminating – the most common gun maintenance issues.

Effective MIG Welding in the Tightest of Gaps

The immense power of the lightweight SWIFT series MIG welding torch from Boostweld makes it effective at a greater distance from the weld joint.

From Design to Programming: The Automated Flow of Weld Information

FASTSUITE Edition 2 Software from CENIT automatically programs the welding path to exactly match the design and adjusts the weld seam position and tool path for changes in part sizes and process geometry.

Micro Laser Welding for Mold Repair, Tool & Die Maintenance

Complete Machining Services uses a LaserStar 8700-3 Series Universal Jig Welding Workstation to meet demands for plastic injection mold repair services.

How to Produce Precise Welds on Highly Alloyed Pipe

ESCO Tool provides a full line of precision bevelers and a pneumatic saw that produces perfectly square cuts with no heat affected zone in all materials and pipe schedules up to 60 in diameter.