Automated Chip Handling and Coolant Filtration for Machining Operations

The flexible, cost effective, self-cleaning EcoFilter conveyor and filtration system from Jorgensen easily fits the existing coolant tanks of machining center and lathe envelopes and can be retrofitted with a kit.

Posted: November 22, 2019

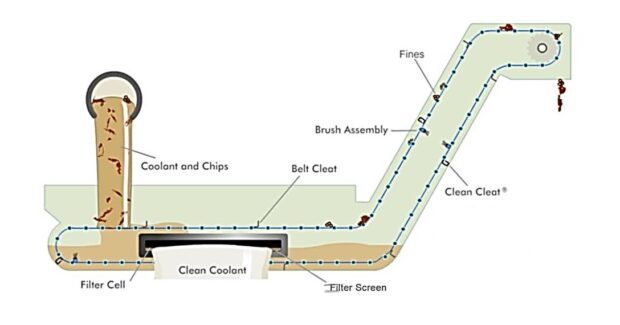

For machine tool chip removal and coolant filtration, the EcoFilter® conveyor from Jorgensen Conveyors, Inc. (Mequon, WI) is a flexible, cost effective, self-cleaning conveyor and filtration system for turning and machining centers that fits the existing coolant tanks of machining center and lathe envelopes easily and can be retrofitted with a kit. A custom engineered EcoFilter-ready conveyor costs no more than a traditional hinged belt conveyor and, using patented Clean-Cleat® technology, a self-cleaning filter cell provides a secondary level of filtration with less chip migration to the coolant tank. Flexible filtration options range from 50 microns to 500 microns and beyond. This conveyor uses a single drive for reduced energy consumption. No consumables are used in this environmentally-friendly system, which can be designed to accommodate both hinge steel belts and drag flight chain styles.

Customers have a “Three Option Approach” to purchasing: They can buy (1) a standard hinged-belt conveyor that is EcoFilter-ready and can be converted to an EcoFilter system with the field retrofit kit within an estimated four hours, (2) an EcoFilter conveyor field retrofit kit, or (3) an EcoFilter conveyor. The EcoFilter conveyor is available in 1.5 in and 2.5 in pitch belt designs. Other options include:

- Choice of belt design, drive systems, safety equipment.

- Pumps / plumbing / coolant transfer.

- Downstream ultra-fine filtration.

- Tramp oil skimmers with tank.

- Complete electrical / UVS Ecologic Control.

- Two types of design configurations are available.

Jorgensen Conveyors, Inc., 10303 North Baehr Road, Mequon, WI 53092, 262-242-3089, Fax: 262-242-4382, info@jorgensenconveyors.com, www.jorgensenconveyors.com.