Mobile Plug-and-Play Cobotic Welding Cart Runs Off Wall Outlet

Powered by a UR10e collaborative robot from Universal Robots, the Vectis Cobot Welding Tool from Vectis Automation is a low-risk, low-cost, easy-to-use system that boosts productivity by reducing the learning curve, deployment time and cost of robotic welding.

Posted: November 29, 2019

The Vectis Cobot Welding Tool from Vectis Automation, LLC (Fort Collins, CO) is a low-risk, low-cost, easy-to-use answer for increasing welding productivity amid the ongoing shortage of skilled labor. It helps boost productivity by reducing the learning curve, deployment time, risk, and cost of robotic welding. Powered by a UR10e collaborative robot from Universal Robots USA Inc. (Ann Arbor, MI), this is a portable, safe, versatile, and extremely easy-to-use system that is even available as a low-risk, no-capital rent-to-own option. The Vectis Cobot Welder is commonly 25 percent to 40 percent less expensive than the all-in cost of a small traditional robot welder. Users are typically set up entirely by the customer within a few hours of system arrival and welding within ten minutes of setup – with no programming experience necessary. The Let’s Weld Together™ intuitive programming interface from Vectis is accessible directly through the UR cobot teach pendant.

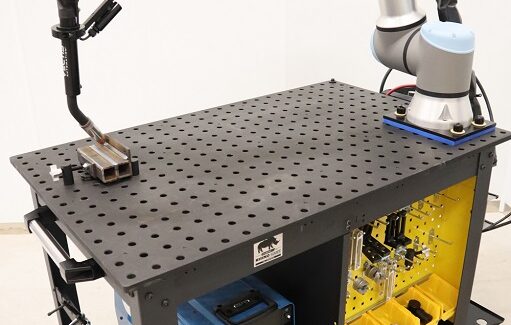

Programs can be created, saved, and later recalled to handle the numerous part numbers typical for high mix/low volume shops. This cobot welder can weld thick and thin parts, and the Vectis Weaving Software allows manufacturers to set weave parameters for cleanly tied-in welds with a Weld Template Library that provides parameter starting points for common weld sizes, such as one-click tack welds, square tubes with tight-radii corners, round tubes, and multi-segment paths. The system comes with all hardware provided fully integrated onto a 3 ft x 6 ft mobile modular fixturing cart, enabling fabricators to bring the cobot to the work or the work to the cobot with no anchoring nor dedicated footprint required. The Vectis Cobot Welding Tool does not need three-phase power, but runs off a 120V wall outlet. The welder can run on anything between 208V and 575V, including 240V single-phase. The cobot welder includes:

- A UR10e six-axis collaborative robot with 51 in reach, an air-cooled welding torch, and intuitive programming on a 12 in touchscreen pendant with Let’s Weld Together intuitive programming interface. The Freedrive Jog Enable Button allows the programmer to teach the robot by physically moving the robot to program points. Embedded safety allows the cobot to safely work alongside humans, without permanent barriers.

- A Rhino Cart® by Strong Hand Tools that includes 66 pieces of modular fixturing and a 30 in x 48 in mobile worktable.

- A Miller 20 Series digital wire feeder and a Miller Invision 352 MPa MIG welder that includes Pulsed MIG waveforms and weld parameters controlled by the cobot.

- Peace-of-mind with a 30-day return policy, a rent-to-own program, lifetime technical support and added flexibility: During production gaps in the weld shop, the cobot arm can be repurposed to other tasks.

- Free application evaluations: A key part of the Vectis process is collaboratively reviewing applications to provide insight on application viability and how to achieve success in production. Suggestions are offered on any upstream fabrication issues and/or how it could be redesigned to make it more automation friendly.

- LTL freight: Most traditional systems require a costly dedicated air-ride semi.