Robotic Welding: What Skilled Labor Crisis?

Take a closer look at how high mix/low volume shops are using automation to improve welding production, address capacity issues and reduce quality variability – all without adding labor.

Posted: November 29, 2019

Adding Business with Pre-Engineered Robotic Welding Cells

Kenosha Metal Products was new to welding automation, but their PerformArc pre-engineered robotic welding cells from Miller were so successful that they took on enough new business to add three additional workers.

Cobot Welding Addresses Labor Crisis and Rising Costs

Powered by a UR10e collaborative robot from Universal Robots, the Vectis Cobot Welding Tool from Vectis Automation is a low-risk, low-cost, easy-to-use system that boosts productivity by reducing the learning curve, deployment time and cost of robotic welding.

Hire a Robot Welder by the Hour

There are no installation costs with BotX Welder from Hirebotics, and shops pay only for the hours the system actually welds, thereby enabling them to hire and fire BotX as their business needs dictate.

Robotic Welding Consumables Reduce Downtime and Skilled Labor Tasks

By reducing the need for replacement, AccuLock R Series Consumables from Tregaskiss increase throughput and efficiency with less human interaction and fewer opportunities for errors in the welding cell.

Revolutionizing the Robotic Welding of Exhaust Components

Advanced process controls for automated MAG welding from Fronius consistently weld complex exhaust components by using high-performance electronics of power sources to adapt the arc in a controlled manner for optimum results.

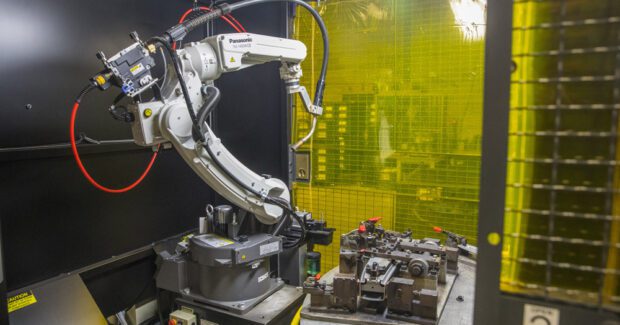

Versatile Pre-Engineered Robotic Welding Cells

Pre-engineered cells from Daihen can increase productivity and reduce operating costs when welding mild steel, aluminum and more.

Robotic Laser Welding and Brazing Eliminates Post-Processing Work

The robust, yet extremely fine, almost invisible seams produced by the ALO4 laser welding and brazing system with tactile seam tracking from Scansonic completely eliminates the need for post-processing in the visible area.