Skilled Hands

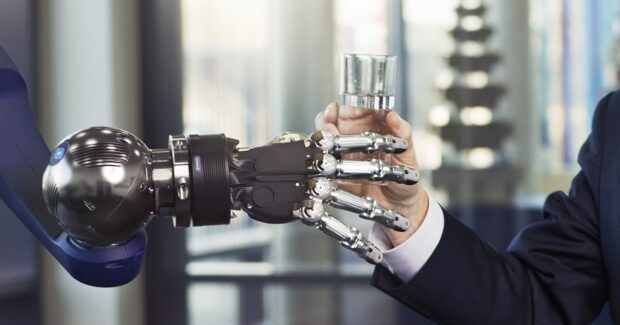

Humanoid manipulators with an ever-higher flexibility of motion are here and will grow in demand in the future because the closer human beings and robots work together, the greater the relevance of five-fingered gripping hands. Here’s why.

Posted: November 22, 2019

The human hand is still regarded as the benchmark when it comes to flexibility of gripping tools. Humanoid manipulators that enable the widest variety of gripping variants will be in ever more demand in the future, particularly when it comes to service and assistance robotics, as the factor of economic viability grows increasingly important. Whereas grippers were previously designed for industrial automation based on robustness, longevity, and performance, with gripping hands the focus is on flexibility of motion. The closer human beings and robots work together, the greater the relevance of humanoid five-fingered hands. In extreme cases, human beings and service robots will share one and the same workstation, including all tools and auxiliary equipment. Precisely for this reason, our SVH five-finger hand was certified by the DGUV as the world’s first gripper for collaborative operation: Its five fingers can carry out many kinds of gripping operations with the help of a total of nine drives. Further, numerous gestures can be performed to facilitate visual communication between humans and the service robot, and increase acceptance for its use in human environments.

SHARING A DESK WITH A ROBOT

In our research projects, we have ascertained that the human hand is much more than just a highly flexible tool for handling. Unlike with industrial grippers, users always associate emotional aspects with humanoid gripping hands. Gripping hands are always in demand wherever a robot has to imitate human handling methods. This concerns manipulation as well as gestures. In our research projects, we have particularly focused on domestic-type applications of service robotics and assembly-oriented applications in industrial assistance robotics. Gripping hands are a sensible option wherever the environment of an activity is configured for human beings, who are then to be assisted by a robot – not only in domestic kitchens, for example, but also in industrial assembly workstations or in picking and logistics applications.

DIFFERENT VARIANTS

In line with the relevant application, we have various gripping hands within our portfolio that start from a two-fingered hand reduced to the basic functions of gripping for service robotics to the industry-compliant SDH three-fingered hand and the complex SVH 5-fingered hand. Our latest SIH model is likewise equipped with five fingers using a structure similar to human beings, but it differs from the SVH fundamentally in terms of drive and kinematics. Whereas the SVH is driven via nine motors and complies with the typical aspects of a precision working robot hand, the SIH is equipped with five motors and actuated via pull cables that are more based on the veins and muscles of its human counterpart. Three of its fingers can be moved independently of one another, and the two smallest in turn move together as a team. As a result, the SIH can be deployed more flexibly than other gripping hands with pull cable mechanisms that are available on the market, while at the same time being more robust and lower in price – a key requirement for the research project, especially when it comes to service robotics applications in domestic environments, where strict management of costs is a must if they are to be successful on the market.

In order to attain the goal of affordable, simple-to-operate five-fingered hands for versatile applications, we make use of experience from bionics as well as the latest motor and electronics concepts. Using intelligent gripper control, a wide range of gripping projects can be realized via a simple-to-operate interface without having to program these precisely.

AUTONOMOUS GRIPPING

Our Smart Labs go one step further: In addition to the gripping component, we are dedicated to the gripping process as a whole and are on the lookout for ways of dealing with handling tasks autonomously. Intricate programming of the robot, which until now had to be done manually by the user or integrator, will be replaced in the future by a learning, autonomous assembly of components. Instead of individually defining positions, speeds, and gripping forces step-by-step, intelligent gripping systems will detect their target objects in the future via cameras and perform gripping planning of their own accord. Based on data records and algorithms, gripping systems will be capable of detecting principles and deriving corresponding reactions. In addition, our research and development teams are working on algorithms for classifying different geometries and arrangements and developing optimum gripping strategies. Gripping systems should be able to handle parts autonomously and refine the underlying gripping workflows ever further.

AUTONOMOUS EVALUATION OF GRIPPING QUALITY

The greater the variance of the parts to be gripped and the more complex the task, the sooner gripping hands will be deployed there too. By means of corresponding sensor systems in the gripper fingers and the motor current and intelligence being integrated in the gripping hand, the quality of a grip can be detected, evaluated, and readjusted if necessary. Also, characteristics of objects, such as geometry, size, or flexibility, can be sensed via the gripper alone and transferred to higher-level systems or upstream/downstream stations. Using artificial intelligence methods, it will also be possible to train service and assistance robots intuitively and create individual libraries for gripper planning and then add to these. Gripping hands for particularly versatile use will then no longer be deployed only for repetitive tasks because it will be possible for them to be continually adapted to new objects and relations and their gripping strategies optimized on an ongoing basis.