A TOOLBOX FOR INDUSTRIAL ROBOT USERS

Program robotics fast with computer-based RobotStudio.

Posted: December 30, 2019

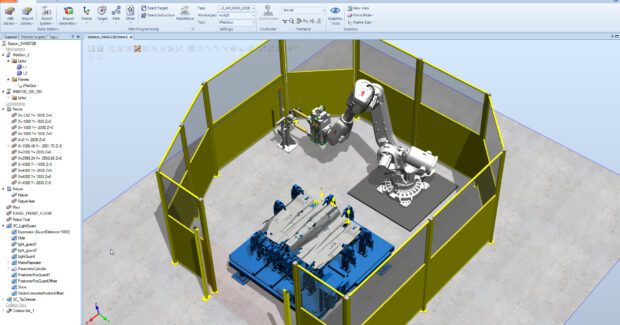

Computer-based programming is the best way to maximize return on investment for robotic systems, resulting in lower costs, faster time to market and superior end products. ABB RobotStudio allows programming to be done on a computer without disturbing existing production.

Improved Collaboration for Better Solutions

System integrators can communicate better with customers and involve them closely through all phases of robot integration, from design through commissioning. The result is that integrators can deliver solutions faster and customers get systems with higher productivity at lower costs. Ultrarealistic graphics with accurate tooling, movements and throughput, mean proposals are easier to understand and clearly communicate the benefits of the system.

More Efficient Design Phase

Given the complexity of modern robotic systems, it can sometimes be a daunting task to ensure all design elements are correct from the beginning. Computer-based system design in RobotStudio ensures you do it right the first time, with the ability to verify tooling, cycle times, work envelopes and product throughput before any construction begins in the real world. Achieving perfectly optimized solutions is made possible because you can quickly and easily try multiple configurations on your PC. You can be certain your system will work properly in the real world after seeing it work in the virtual world. The end result is greatly reduced risk.

Built on Virtual Robot Technology

RobotStudio is built on the ABB Virtual Controller, an exact copy of the real software that runs your robots in production. This ensures everything in the virtual world works exactly how it will in the real world, by using real robot programs and configuration files identical to those used on the shop floor.

The Best Way to Program Robots

The processing power of the computer can be used to automatically generate paths based on supplied CAD models, resulting in superior end products. New products can be added to existing lines in the virtual programming environment without disturbing existing production in the real world. For programmers, this method of programming is far more efficient and can be done without the pressure of time or the constraints of preexisting equipment locations. By lowering the barriers to robotic integration through ease of programming, customers and integrators both see reduced costs and faster times to market.

Instant Return on Investment

Increased uptime, improved productivity, faster time to market and better quality add up to a virtually instantaneous return on investment for RobotStudio.

Freemium Business Model

The features of RobotStudio are split into Basic and Premium functionality. The Basic functionality can be used free of charge, whereas the Premium functionality requires a paid subscription. CAD converters and PowerPacs require separate subscriptions.

3D Import and Modeling

RobotStudio can import CAD data in a number of formats. With the available layout functions you can position your parts the way you want. Using Mechanism Modeler, you can model your own tracks, tools or grippers for use in RobotStudio simulations.

Smart Components

Smart Components offers a way of creating simulations by adding behavior to the simulated objects. It brings life to the graphical component libraries by the addition of so-called Base Smart Components for basic motion, signal logic, arithmetic, parametric modeling, sensors and so on.

AutoPath and AutoConfiguration

By using a CAD-model of the part to be processed it is possible to automatically generate the robot positions needed to follow a curve or edge of the geometry. The AutoConfiguration feature helps you to automatically define the robot arm configuration for a complete path.

Path Tools

Tools are available to tune an entire path. You can smooth out the orientation, reposition and mirror the path to get the robot to do exactly what you want. You can compensate the path for the radius of the tooling used.

Robot Program Editing and Debugging

The integrated robot program text editor allows you to view and edit programs loaded into your robot, either real or virtual. Its features include syntax and error highlighting, tooltips, automatic insertion of arguments, and context-sensitive help for robot instructions. There is a data editor that allows tabular editing of program data. You can debug the program by setting breakpoints, step through the program and watch variable values.

Jobs

The Jobs feature lets you operate on a large population of IRC5 controllers in the plant. There are several actions that can be carried out by the Jobs function, for example, do a backup, synchronize the time of your robots, read RAPID data, get system information and much more.

Visual SafeMove

Visual SafeMove is a 3D-based configuration tool for SafeMove. The configuration tool allows safety zones to be configured and visualized using the 3D graphics view. It is part of the Basic edition which means it is free of charge. It works for both real and virtual robots.

TrueMove Path Visualization

The IRC5 controller features TrueMove that provides outstanding path following capabilities. When working with an ABB robot you can be confident that the robot will always follow the programmed path regardless of the programmed speed. In RobotStudio, the programmed path will be visualized to show exactly how the robot will move.

Signal Analyzer

The Signal Analyzer records and displays signals from a robot controller which makes it possible to optimize the robot program. For example, you can record robot speed, power consumption, I/O signals, TCP and joint values. Signal recordings can be exported to Excel for further analysis.

Virtual FlexPendant and ScreenMaker

The Virtual FlexPendant allows you to control and monitor the virtual controller in the same way as the real controller. You can for example use it to preview user screens created with ScreenMaker which is a tool in RobotStudio for developing FlexPendant user screens without the need to learn the Visual Studio development environment and .NET programming.

Visualization

The DirectX 11 based 3D graphics engine in RobotStudio enables the user to customize the light setup by adding and tuning the light sources available: ambient light, infinite light, spotlight and point light. The shadows cast by the objects in combination with the built-in material library gives a realistic touch to the visualization of your result. In addition, you can define view points and create markups.

Station Viewer

RobotStudio can create a 3D interactive movie packaged in a standalone executable for showing and sharing a RobotStudio simulation to others that do not have RobotStudio installed. During replay, the speed can be adjusted to run faster or slower than real-time. A slider can be used to jump directly to the simulation highlights.

Transfer

The transfer function allows easy transfer of offline-created robot programs to the real robot on the shop floor. This means that you can transfer data from a virtual controller (which is offline) to a real controller (which is online). You can also compare the programs of the real and virtual controllers.

PowerPacs

A PowerPac is an optional addition to RobotStudio for certain application specific tasks.