Additive Manufacturing Path Optimizer

AM Path Optimizer simulation technology from Siemens helps maximize the production yield and quality of powder bed fusion manufactured parts by solving overheating challenges and reducing scrap.

Posted: December 5, 2019

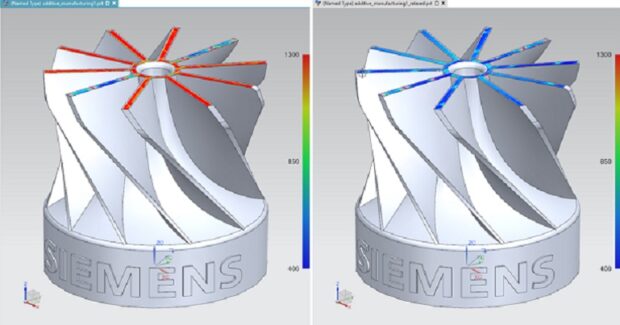

Additive Manufacturing (AM) Path Optimizer from Siemens Digital Industries Software (Plano, TX) is a beta technology integrated into NX™ software to help users solve overheating challenges and help reduce scrap and increase production yield to achieve the industrialization of AM, or the use of AM at the industrial scale. This next generation advanced simulation technology can help maximize the production yield and quality of powder bed fusion manufactured parts and is another extension to an end-to-end AM solution that feeds the digital thread and informs each step of the industrialized additive manufacturing process. Building on the Simcenter Additive Manufacturing Process Simulation solution, AM Path Optimizer complements a strategy for the digital twin of the manufacturing process and addresses errors originated from suboptimal scan strategies and process parameters that can lead to systematic failures due to overheating, which can cause scrap and inconsistencies in component quality.

The beta technology uses an innovative approach of combining physics-based simulation with machine learning to analyze a full job file in only a few minutes before execution on the machine. This technology is expected to help achieve “first time right” prints and drastically reduce trial and error. It can also help reduce printing costs and enable the printing of components that are nearly impossible to achieve today. It has demonstrated success with TRUMPF Inc. (Farmington, CT) as a partner. “With the AM Path Optimizer, both companies can push industrialization of additive technologies further forward,” said Jeroen Risse, an AM expert at TRUMPF. “In our demonstrations we saw an improvement of geometrical accuracy, elimination of re-coater errors caused by overheating, as well as a more homogenous surface quality. Also, the scrap rate is expected to be reduced significantly.” Siemens is actively engaging early adopters to further prove out the AM Path Optimizer.

Siemens Digital Industries Software, 5800 Granite Parkway, #600, Plano, TX 75024, 972-987-3000, www.sw.siemens.com.