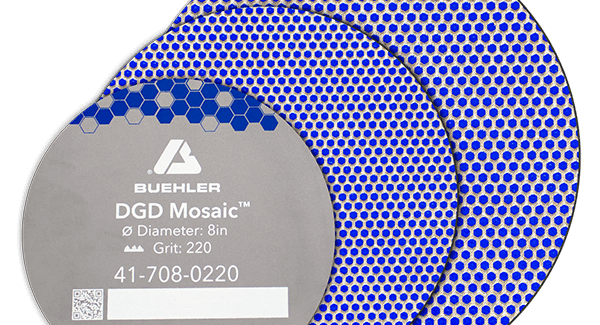

Diamond Grinding Discs for Superior Stock Removal on Difficult Materials

Mosaic diamond grinding discs from Buehler effectively and consistently grind steel, sintered carbides, alloyed metals, thermal spray coatings and other hard materials with an improved material removal rate that reduces operating costs.

Posted: December 6, 2019

For demanding laboratories working with heavy duty metals or durable materials, Mosaic diamond grinding discs (DGD) from Buehler Ltd. (Lake Bluff, IL) provide superb material removal in the grinding process of sample preparation. The high-strength abrasive surface of the DGD effectively grinds steel, sintered carbides, alloyed metals, thermal spray coatings and other hard materials. The Mosaic DGD provides users with an enhanced material removal rate, consistency in results, labor savings and an extended lifetime that saves on repeat purchases. Mosaic DGDs are available with a magnetic backing and come in 8 in, 10 in or 12 in discs in 120, 220, 320, 400 and 1,000 grit sizes. For ultimate results, they are partnered with the EcoMet or AutoMet family of grinders. The extended lifetime of Mosaic DGDs provides a cost effective, yet fast and high quality way to save time for production quality control technicians in many applications: They are optimal for grinding hard and heat-treated steels and other alloyed metals used in the automotive industry, they are ideal for super alloys and thermal spray coatings used in aerospace, and machine shops use them to grind cemented carbides and hard metals in toolmaking.

Buehler Ltd., 41 Waukegan Road, Lake Bluff, IL 60044, 847-295-6500, www.buehler.com.