Home /

High Precision Free-Form Waterjet Cutting High Precision Free-Form Waterjet Cutting

FiveX abrasive waterjets from Water Jet Sweden can perform five-axis 3D finishing of fabricated structures, pressed parts, molded composite parts and other 3D parts made of hardened steel, titanium, Kevlar and carbon fiber.

Posted: December 3, 2019

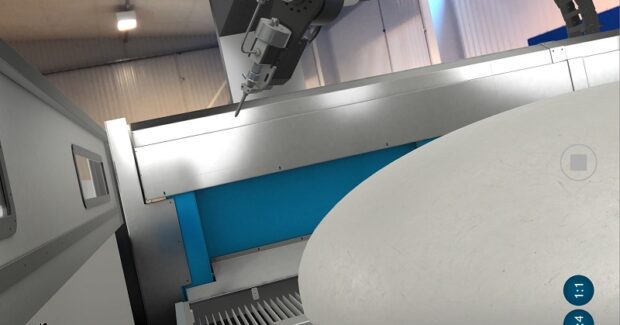

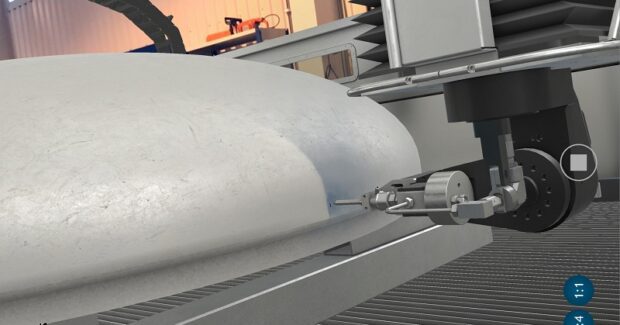

The heavy duty FiveX abrasive waterjet cutting machine from Water Jet Sweden is built with the most advanced technology and an exceptionally stable design to perform high precision free form cutting of full 3D components. With Z-axis capacities up to 1,500 mm and a generous working area, it is ideal for large-scale 5-axis free form finishing of fabricated structures, pressed parts, molded composite parts and other 3D parts made of hardened steel, titanium, Kevlar and carbon fiber, as well as trimming molded parts into their final shape for defense, aerospace and power applications. (first view)

The heavy duty FiveX abrasive waterjet cutting machine from Water Jet Sweden is built with the most advanced technology and an exceptionally stable design to perform high precision free form cutting of full 3D components. With Z-axis capacities up to 1,500 mm and a generous working area, it is ideal for large-scale 5-axis free form finishing of fabricated structures, pressed parts, molded composite parts and other 3D parts made of hardened steel, titanium, Kevlar and carbon fiber, as well as trimming molded parts into their final shape for defense, aerospace and power applications. (second view)

The heavy duty FiveX abrasive waterjet cutting machine from Water Jet Sweden is built with the most advanced technology and an exceptionally stable design to perform high precision free form cutting of full 3D components. With Z-axis capacities up to 1,500 mm and a generous working area, it is ideal for large-scale 5-axis free form finishing of fabricated structures, pressed parts, molded composite parts and other 3D parts made of hardened steel, titanium, Kevlar and carbon fiber, as well as trimming molded parts into their final shape for defense, aerospace and power applications. (third view)

The heavy duty FiveX abrasive waterjet cutting machine from Water Jet Sweden is built with the most advanced technology and an exceptionally stable design to perform high precision free form cutting of full 3D components. With Z-axis capacities up to 1,500 mm and a generous working area, it is ideal for large-scale 5-axis free form finishing of fabricated structures, pressed parts, molded composite parts and other 3D parts made of hardened steel, titanium, Kevlar and carbon fiber, as well as trimming molded parts into their final shape for defense, aerospace and power applications. (fourth view)

Heavy duty FiveX abrasive waterjet cutting machines from Water Jet Sweden AB (Ronneby, Sweden) are built with the most advanced technology and an exceptionally stable design to repeatedly perform high precision free form cutting of full 3D components. Large-scale 5-axis processing allows the advantages of the waterjet process to be utilized in free form finishing of fabricated structures, pressed parts, molded composite parts and other 3D parts. With Z-axis capacities up to 1,500 mm and a generous working area, this waterjet technology has been embraced for precision cutting of hardened steel, titanium, Kevlar and carbon fiber, as well as trimming molded parts into their final shape for defense, aerospace and power applications. Since the FiveX gantry cuts in all directions, it has full size wall design and automated stainless steel side and frontal protection. The machine uses an intelligent probe interface that integrates a work piece indicator (Renishaw probe interface) with a large library of pre-designed measurement cycles. Customized measurement cycles can be delivered as an option.

The FiveX has a stainless steel cutting table/tank, heavy duty stainless steel protection covers and a linear drive (X) and ballscrew (Y) motion system. Its Panel One HMI control unit and Fanuc CNC provide maximum Z-movement of 1,500 mm; positioning accuracy of ± 0.050 mm/m; repetition accuracy of ± 0.025 mm; cutting performance of 90 deg; A-axis movement of ± 91 deg and C-axis movement of ± 220 deg; and A- and C-axis transmission accuracy of less than 1 arcmin and repetition accuracy of less than ± 6 arcsec. The HMI provides monitoring and control of the electronic abrasive feeder, proportional valve pressure and HP pump. The machine is available with 4,000 bar and 6,000 bar pressure technology and comes in sizes 2.5-4 m wide x 2-6 m long as standard.

Water Jet Sweden AB, Teknikvägen 4, S-372 38 Ronneby, Sweden, +46 457 455 440, sales@waterjet.se, waterjetsweden.com.

Subscribe to learn the latest in manufacturing.