LARGE ABRASIVE CUTTER AND MEDIUM SECTIONING SAW

An automatic saw and a tabletop saw from Buehler provide consistency and repeatability in cutting production samples, saving preparation time in the quality control or inspection laboratory. Confidently cut production samples including automotive drive trains, gears, crankshafts, and engine components.

Posted: December 30, 2019

Two saws from Buehler (Detroit) provide consistency and repeatability in cutting production samples, saving preparation time in the quality control or inspection laboratory.

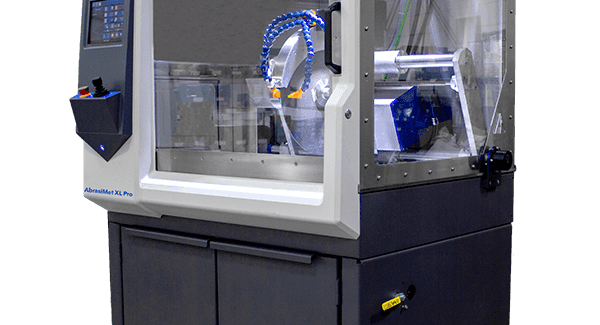

The automatic AbrasiMet XL Pro cuts parts up to 7 in (178mm) in diameter. A chamber that fits parts up to 48 in (1220 mm) wide and 13.4 hp motor allow for fast sectioning of large workpieces.

Operators use the machine’s touchscreen to create and save multiple sectioning programs based on blade size, cut type, feed rate, cut length, serial cutting, homing and tracking position, and chamber washdown. When processing a variety of parts, the operator loads the program for each sample and the machine does the rest.

The machine features a movement-tracking system to allow for precise cutting parameters and a green laser for easy X-alignment. One joystick controls all three-axis movement of the cutting arm and T-slot table, which allows the blade to be precisely positioned. With precise X, Y, and Z movement of the blade, multiple cuts can be made with one programmed cut.

Sectioning modes minimize deformation by minimizing the area of contact during cutting. Planar mode, for example, pulses the cut to reduce the potential for thermal damage. “Smart Cut” optimizes feed rate when cutting materials of varying geometry and abrasion-resistance.

A quick-lock nut saves time when changing blades by allowing users to manually loosen and tighten the nut onto the spindle.

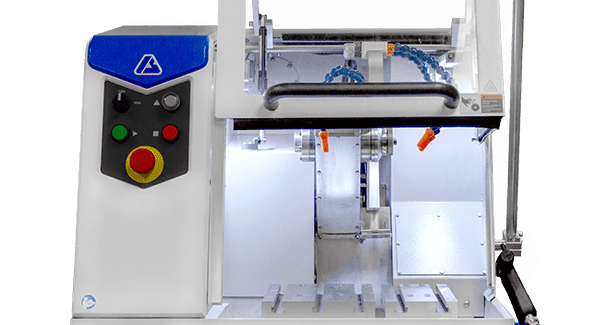

The benchtop AbrasiMet M is designed for quality control and inspection of parts up to 25 in (635mm) in the chamber. Improvements to the manual machine include a dual-blade application to ensure parallel cuts, higher range of sample shapes, and lower overall sectioning time; and optimized rpm settings to maximize performance of the 10-in (254mm) and 12-in (305mm) blades.

LED light strips increase visibility of samples. Adjustable cutting-arm handle improves user ergonomics.

The casting is durable with a corrosion-resistant stainless steel T-slot table. Reinforced hood stands up to repeated opening and closing, and enclosed motor-cutting arm system keeps debris and coolant out to maximize motor life.

Lab technicians don’t need tools to change blades. Easy-access valve and washdown hose.

Buehler, 41 Waukegan Road, Lake Bluff, IL 60044, 847-295-6500, www.buehler.com.