THREE SMART TOOLS FOR SMART FACTORIES

Festo is distributing a new line of magnetic grippers and giving you the ability to design your own 2- or 3-axis industrial robot.

Posted: December 24, 2019

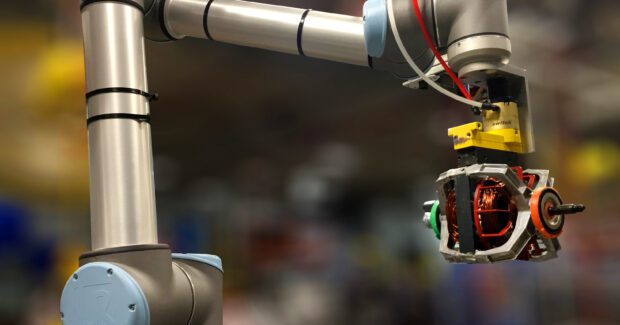

Best-suited for handling small parts, picking, or working in close proximity to humans, Festo Corp.’s (Islandia, NY) DHEF adaptive-shape gripper holds a range of shapes, unaligned objects, and several objects at once without the need to change grippers.

The form-fit gripper consists of a pneumatic drive and an inverting cap connected to the piston rod at its tip. The cylinder motion pulls the cap tip inwards, allowing objects to be gripped during the inverting motion.

Two sensors can be mounted in T-slots on the cylinder’s side to report piston position and provide feedback on the gripping process. ISO interface supports mounting on a robot.

Festo’s also begun distributing eight switchable grippers from Magswitch Technology (Lafayette, Colo.) that integrate with Festo’s electric and pneumatic motion systems for robotic welding, pick-and-place, and body-in-white applications:

- E Series (electrically actuated tools)

- J Series (integrated sensor for double-blank detection)

- T Series (precision-fit tools)

- AR Series (pole shoes customizable to any geometry)

- PLAY Series (multiple magnets handle long and heavy pipes and beams)

- D85 (narrow footprint for picking sheet metal)

- M10AY ASC (for handling thinner parts or lifting to shear)

- Sheet Fanner (separates steel blanks)

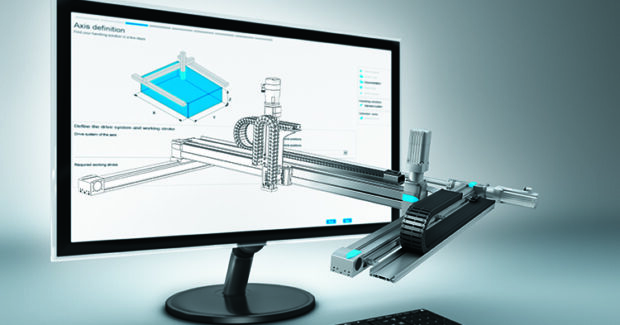

DESIGN YOUR OWN CARTESIAN ROBOT

Handling Guide Online cuts engineering, assembling, and programming costs. After you enter application parameters such as load and speed, the tool designs a control panel and 2- or 3-axis robot that comes fully assembled with CAD data and commissioning files.

Festo Corp., 1377 Motor Parkway, Suite 310, Islandia, NY 11749, 631-435-0800, www.festo.com.