ANCA Updates ToolRoom RN34 Software

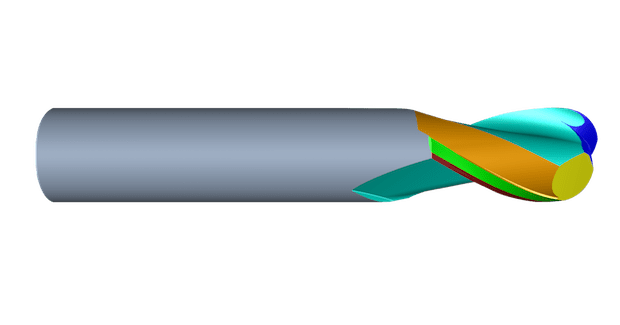

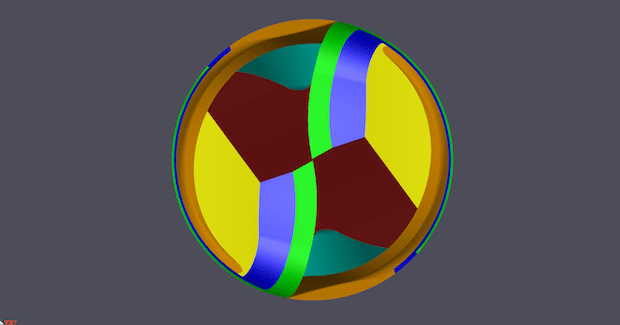

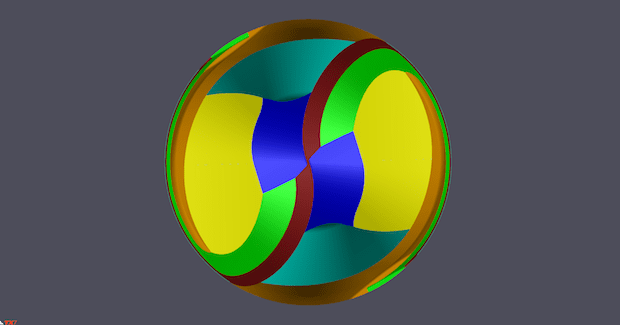

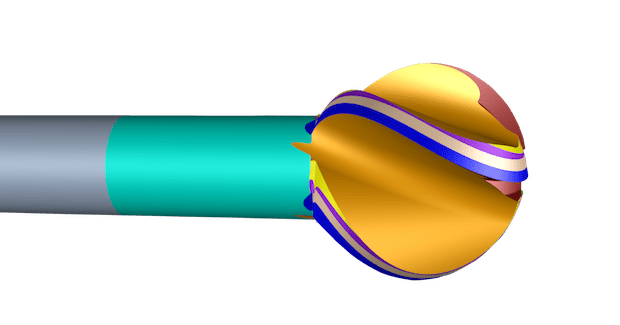

In addition to several new tool types, the package reduces setup time from hours to 5 minutes via a new tool-balancing feature and provides an intuitive interface for creating complex endmill geometries that minimize chatter. For example, the constant-helix ballnose option is replaced by a graphical drag-and-drop designer with optimized irregular helix curves to reduce vibration and near-instant visualization by switching from 2D to 3D projection of the cutting edge.

Posted: January 29, 2020

ToolRoom RN34 is the latest generation of ANCA’s (Wixom, MI) software.

Designed for the aerospace, die mold, general machining, and power-generation industries, the new package promises improved productivity through the intuitive creation of complex endmill geometries; tool balancing to increase tool life, cutting volume, quality, and workpiece precision; and chatter minimization via simple design of high-performance, complex tools. ToolRoom RN34 provides design flexibility from simple to challenging tasks, supporting both manufacturing and regrinding applications.

Technical Information on New Features

The new ball nose cycles allow end users to manufacture a range of ball nose tools suitable for finishing and roughing. The designer edge accommodates high helix on ball cutting edge for better fracture resistance and less vibration due to the irregular curve.

- Ball nose with designer cutting edge.

- New chisel edge grinding method.

- Curvature gash – curved gash surface.

- Flute gash – curved ball gash and fluting in single move.

- Facet gash with periphery of 1A1 or 1V1 wheels.

- Bullet and bullnose style tools.

- 11V5 wheel grinding methods for improved wheel life.

- Square to ball nose blank roughing cycles.

- Various other methods of OD grinding with 11M2 wheels.

Double Radius Corner

The double corner radius allows barrel- or lens-shaped tools with larger to smaller or smaller to larger radius from the end of tool. Vibration and deflection are reduced with this style of geometry, and the thinner chips formed provide longer tool life and enhanced performance.

- Barrel shape – large radius to small towards the end of tool.

- Lens shape – small to larger radius towards the endface.

- Curved endface design.

- Roughing operation for corner radius tools.

Flute Cycles

Fluting cycles provide manufacturing for variable helix and pitch tools to eliminate the harmonics caused during high-speed machining, by varying the time intervals between flute contact with the workpiece. Flute cycles support the following option combinations:

- Variable helix with NAS hook.

- NAS hook with radial land.

- Variable helix and pitch with radial land.

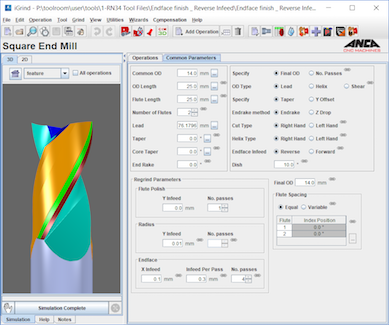

Square End Mills

- Support for reverse infeed when using large dish angles on square end mills to manage wheel wear with number of passes.

- Ability to choose between forward and reverse infeeds.

Outer Diameter (OD) Chip Breakers

New operation in end mill cycles to add outer diameter chip breakers in automatic or manual modes. Applicable to all straight outer diameter profiles to complement corner radius, ball nose, side and face cutters, and endface operations. A library of all ANCA-supplied collet adaptors and collets is available for the user.

Embedded TOM Files

This adds additional functionality in allowing one TOM file to be embedded into another TOM file; for example, a corner radius with multidrill gash.

- Like the iPunch operation in iGrind and KHP.

- Some limitations exist, such as use of tool segments.

Helical Fir Tree Cutters

Support for a wide range of constant helix, constant lead, and shear cutters used in the aerospace and power generation industries. All are supported for unmanned production with the support of the integrated, fully automated LaserPlus.

- Support for constant helix fir tree cutters.

- Helical fluting with hook generating a flat flute surface.

- Support for iView and LaserPlus.

Drills

A new feature is added to OD backoff/raised land fluting operation to produce second margin toward tool’s trailing edge.

- Double margin can be produced in both the backoff types OD and raised.

- The second margin can also float at an offset angle from cutting edge of the tool.

- This feature is made available to drills and step tools.

Thread Mill

Manufacturing a variety of threadmills is possible now that thread mill grinding and cresting operations are supported with formed and standard fluting operations.

- Support for drill thread mill, straight OD, tapered OD, and all combinations.

- Possible to grind insert style or single rib thread mills.

- LaserPlus support for large volume production.

Pocket Grinding

Pocket grinding software allows users to quickly and easily define PCD pocket geometry. This is required for PCD tools used mainly in the aerospace industries for composite and non-ferrous materials.

- Ability to specify pocket geometry as common or for individual flutes.

- Position of pockets can be fixed or alternated based on flute number.

- Supported with spindle speed increaser hardware on all platforms for mounted point wheels.

ANCA Inc., 31129 Century Drive, Wixom, MI 48393, 248-926-4466, usainfo@anca.com, www.machines.anca.com.