Two New End Mills from Kennametal

A 4-flute, solid carbide end mill delivers superior performance for steel, stainless steel, high-temperature alloys, and cast iron. A 5-flute end mill maximizes aluminum roughing for aerospace machining.

Posted: January 29, 2020

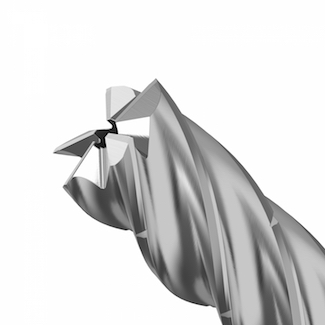

With its new flute design, the Harvi I TE 4-flute solid carbide end mill from Kennametal Inc. (Latrobe, PA) addresses four problems that affect more than 90% of all milling applications: chip evacuation, tool deflection, corner stability, and breakage due to radial cutting forces.

The flutes’ design helps curl and break chips into manageable pieces, while a series of chip gashes within the flute lift those chips up and away from the workpiece. Both promote coolant flow and eliminate chip re-cutting to improve tool life. The twisted end-face and unique gashing promote chip evacuation while also improving ramping and plunging capabilities.

Its parabolic core reduces tool deflection and enables an eccentric, faceted relief along the entire flute length, decreasing cutting friction and increasing edge strength. Combined variable helix angle and asymmetric flutes dampens vibration before it can affect machining operations.

With reduced cutting forces, the tool can be used on any machining center or mill-turn center.

Designed to maximize productivity of high-velocity aluminum roughing in aerospace machining, the KOR 5 solid carbide end mill increases table feed rates up to 66% compared to 3-flute tools. The tool is designed to remove and move large amounts of metal from the work zone as quickly as possible. Its tapered core, variable pitch design, and 35-degree helix eliminates chatter and tool deflection. The coolant throughout the tool flushes chips away while reducing heat. Designed to break up long chips, the chip splitter pattern improves surface qualities by eliminating re-cutting.

The tool has potential to become the new standard for machines utilizing CAD/CAM tool paths. KOR 5 has more active contact points than a 2-fluted or 3-fluted end mill, which improves stability and eliminates chatter even on heavy cuts. Applying the tool with low radial engagement and high depth of cut results in higher metal removal rates than traditional methods.

To assure predictable, no pull-out performance at maximum feed rates, the KOR 5 is available with Safe-Lock shanks.

Kennametal Inc., 1600 Technology Way, P.O. Box 231, Latrobe, PA 15650-0231, 724-539-8033, carsten.gromoll@kennametal.com, www.kennametal.com.