Hybrid-Coated EDM Wire Increases Productivity 15% to 20%

More than 50% of Clippard’s pneumatic valve and cylinder production is done via wire EDM. When Global Innovative Products (GIP) needed real-world validation of its testing on Plasma, a gamma-phase intermetallic zinc alloy-coated wire with brass core, Clippard successfully used the wire to produce tooling.

Posted: February 6, 2020

A few years ago, Clippard (Cincinnati) engineers and manufacturing specialists developed an “air guitar” that runs on the company’s pneumatic valves and cylinders. The video of that invention performing Pachelbel’s Canon in D major demonstrates the third-generation, family-owned and -operated manufacturer’s approach to business: have fun finding new ways to do things faster and less-expensively.

The company’s two ISO-certified Ohio locations produce components sold worldwide for multiple industries, work that involves 12-axis CNC Swiss machines and CNC milling centers, anodizing, electroless nickel (EN) plating, and thermal deburring. The company also uses wire electrical discharge machining (EDM) to make all its tooling. One-offs are common, so speed is critical.

When the circuit boards on one of the company’s Ocean Technologies Co. (a Taiwanese brand distributed in the U.S. by Methods Machine Tools) hole poppers needed repair, Barry Ramsay of EDM consumables supplier Global Innovative Products (GIP) (Mason, Ohio) proposed a trade. GIP’s newly developed coated brass wire, called Plasma, had proven out in lab tests but needed real-world production validation.

“He proposed exchanging the board servicing for the opportunity to test the wire on one of our Fanuc wire machines,” says Clippard CNC/EDM Programmer Trevor McCoy. “I knew from previous experience that Brad was able to do that kind of work. Seemed reasonable to us, so we agreed.”

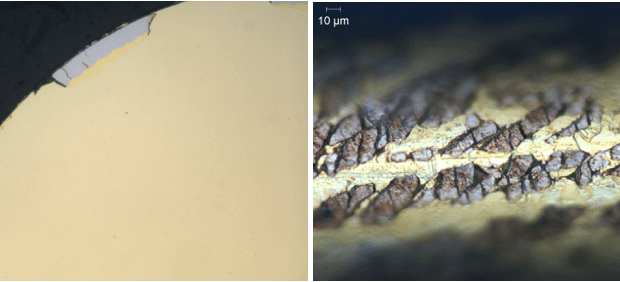

Plasma gamma phase brass is a brittle intermetallic alloy (Cu5Zn8) with a high zinc content (approximately 65%) that can also be synthesized by a diffusion anneal. However, when such coatings are wire-drawn subsequent to the anneal, the coating fractures and redistributes around the wire’s circumference, creating a discontinuous layer sometimes described as a “porous layer” that promotes turbulent flow enhancing the flushing of debris. However, zinc enrichment created at the surface combined with the elevated melting point of CuZn gamma phase (approximately 800 degrees C/1472 degrees F) contribute to the performance of the coated wire.

GIP found Plasma suitable for all wire machine types, with excellent auto-threading capability and increased performance even at conventional brass wire settings. Ramsay was confident the product would outperform what Clippard was using – including other GIP wire.

“We knew they were running all types of materials and some very high-precision tooling used in their own machine shop to produce components with very tight tolerances,” he says. “The characteristics of the wire in production on the Fanuc machine were important, as the flushing of their precision components directly impacts quality.”

The handshake deal was a classic collaboration between two companies for their mutual benefit. Application engineering supplied by GIP facilitated Clippard’s experience because the test learning-process information was shared without reservation.

“We do a lot of custom work for our own use,” McCoy says. “Some hard tool steels are difficult to drill. The jobs require a lot of setup time and fixturing, so run time, finish, and wire breaks are all critical for us.”

Clippard used Plasma to produce parts for robotic arm articulation. McCoy notes they held tolerances under a tenth, with a microfinish that was very important for the application. One tool for a medical part was produced in 56 seconds vs. 1:05 with five skim passes, a 16% improvement in overall production.

“We could apply more power to run faster,” says McCoy. “Plasma consistently outperforms premium brass, based on my experience with both now.”

He also says Plasma wire is as clean as conventional brass. With its competitive price point, less of a premium is required to achieve enhanced results.

Clippard, 7390 Colerain Ave., Cincinnati, OH 45239, 877-245-6247, www.clippard.com.

Global Innovative Products (GIP), 7697 Innovation Way, Suite 200, Mason, Ohio 45040, 513-701-0441, info@gipintl.com, www.gipintl.com.