Parts Distributor Becomes Profitable Job Shop After Deploying Flexible Manufacturing System

What with designing tombstone fixtures, selecting tooling, and programming the operations, the time and money required to buy and use a flexible manufacturing system (FMS) may be off-putting. But as this Massachusetts manufacturer learned, the investment brings peace of mind by providing financial stability.

Posted: February 20, 2020

Dan Olsen had no formal training as a machinist when his distributorship couldn’t source a part that customers had begun requesting. But he does have an MBA in product design and manufacture, so he decided to reverse-engineer the piece and see if he could make it himself.

At the time, Olsen was co-founder of www.BoatZincs.com, the world’s largest online source of aluminum, magnesium, and zinc sacrificial anodes for the marine industry. “Zincs” are attached to the iron and steel hulls, propellers, and other below-waterline parts of vessels to keep the metal from corroding. Launched in 2004, BoatZincs sells more than 1,200 zinc, aluminum, and magnesium parts to more than 50,000 recreational and commercial boat owners, and prides itself on same-day shipment with no added shipping costs.

Olsen began BoatZincs.com’s venture into manufacturing when, citing tooling costs and demand speculation, suppliers were reluctant to produce a particular propeller anode. “That’s when we decided to reverse engineer the part and start manufacturing these parts ourselves,” he says. “We built our own small furnace and started die casting in my driveway.”

Olsen has engineering and MBA degrees from Boston’s Northeastern University, and helps develop the advanced manufacturing curriculum for a local high school. He taught himself how to machine die casting tooling and parts after buying CAD/CAM software and using it to generate machine tool G-code.

To begin manufacturing, he rented a 1,500-square-foot industrial building, bought a used CNC bed mill with no tool changer, and started machining die-casting tooling. After about a year, his engineering friends in other businesses began asking him to make parts they couldn’t get manufactured elsewhere. Some of the first parts were for aerospace research and development.

That value-add approach to service became a second business that works with customers’ engineers to keep costs low and quality high by designing for manufacturability. As the list of non-marine customers grew, Olsen decided to clarify the company’s image by creating Mach Machine Inc. “Mach” is a measure of airspeed and Olsen “just liked the way it sounded,” especially in relation to the aerospace segment of the company’s business.

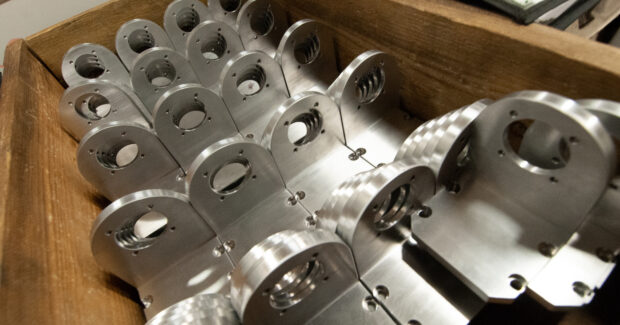

Today, BoatZincs.com’s offshoot business manufactures precision part prototypes and production runs for customers in the high-tech, medical, aerospace, and defense as well as marine industries. Olsen takes an engineer’s approach to machining processes and fixturing, designing them to minimize cycle times and maximize machine work envelope.

Don’t Fear Flexible Manufacturing

Mach Machine soon acquired a CNC vertical machining center (VMC) to improve cycle times, tool life, and production flexibility. Next came a turning center and another VMC. “We started adding equipment as our business started to grow,” Olsen said.

To improve cycle times, tool life, and production flexibility, the company bought a 3-axis Haas Automation Inc. VF-2SS vertical machining center (VMC), the company’s most-popular Super Speed model. Next came Okuma’s Genos L300-MYW dual-spindle turning center with a 10-inch Kitagawa-Northtech chuck on the main spindle, and another VMC.

To handle a large contract from a laser equipment company that involved machining five sides of a lens mount, Olsen designed and mounted a custom trunnion table on the VMC’s rotary table. The arrangement indexed the part to different positions and permitted 4-axis positional machining without having to stop, re-fixture, and touch the part in mid-operation. With a 24-minute cycle time, Olsen says, “we had a good rate on that part and it turned out to be pretty profitable.”

Mach Machine next blended multitasking technology with automation by combining its CNC turning center, which featured live tooling, with a bar feeder. The turning center facilitated one-and-done mill-turn work while the bar feeder enabled the machines to work lights-out while maintaining repeatability and quality.

Inevitably, as mix and volume grew, the time required to construct multiple setups grew as well. After watching an employee take four hours to perform a setup that repeated every month, Olsen realized it was time to investigate a horizontal machining center (HMC) that would enable the company to design and build fixturing setups on tombstones and leave them in place permanently.

He was researching options when his Okuma machine tool representative invited him to a demonstration of an Okuma MB5000H HMC and a flexible manufacturing system (FMS) from Fastems LLC, which makes automation equipment and software.

“I just wanted to get my feet wet in the horizontal machining area, but this was more like taking a dive,” Olsen says. “But I realized we didn’t have just one job that could go on this machine. We had dozens.” The demonstration convinced him to buy the machine and a 12-pallet Fastems FMS One with automated stacker crane and MMS5 production planning and execution software.

“We got that up and running January 2017 and never looked back. It was the best decision we ever made.”

Cycle Time Falls Almost 60%

The combined HMC/FMS system’s efficiency prompted Mach Machine to use it for a growing amount of work, including both aluminum and stainless-steel parts. However, having one HMC running different alloys was difficult in terms of clearing out chips and changing collection bins to avoid mixing chips. As a result, Olsen added a second MB5000H and expanded the Fastems FMS to 24 pallets.

“So now we have two dedicated machines – one for aluminum, one for stainless steel – and they’re busy,” he says.

In addition to streamlining setup, the system decreased cycle time on the five-side lens mount to 10 minutes per piece, a 58% reduction. “The fixturing is designed specifically for the part, so we’re able to use the machine’s entire work envelope,” Olsen says. “Permanent fixturing also gives us excellent part-to-part repeatability.”

By facilitating production of parts on demand, the system also helps keep inventory levels low. Most of the work that goes into it is blanket purchase orders with monthly deliveries. “Once the jobs are in there, they’re there permanently,” Olsen says. “That makes re-running the job like gravy.”

He urges shop owners not to be intimidated by the technologies required to become flexible manufacturers.

Yes, setting up a system isn’t easy, what with designing tombstone fixtures, making tooling selections, and programming the operations. However, he says, “once we got that first job in rotation, it got easier and easier,” he says. “We now have a process so that when we put a new job in, we know what we have to do and what to expect.”

Also, the technology “rewards you on an order of magnitude greater than your initial investment. You just need to be patient and reach out to the manufacturers tech support and online resources like YouTube and online forums to find answers.”

Optimizing Planning and Scheduling

Mach Machine uses Shoptech Corp.’s E2 Shop System enterprise resource planning (ERP) system to manage customer orders, part cataloging, inventory information, and purchasing. It isn’t integrated with the machines and FMS, but may be in the future.

The Fastems FMS software collects machine data that facilitates proactive tooling strategies. The system collects wear and breakage information for every tool and uses that data to optimize tool application.

For example, if data shows a certain drill often breaks or wears out after drilling 500 holes in a particular part, the software can prompt replacement when the tool completes 450 holes. Rework needed due to tool failure is minimized, and the shop’s yield rate of over 99.5% annually reflects that, according to Olsen.

The software also manages job sequencing to maximize efficiency, resource utilization, and timely delivery.

When raw material arrives, the shop sends a job traveler file to the machine. The operator enters job number, part number, quantity, and due date. Permanently set-up job-specific pallets are brought to the load station via the automated Fastems FMS stacker crane and the operator loads them with raw material. The software takes over from there. Even though a job is queued up and ready to go, it might be machined at night or the next day because other jobs have higher priority.

“The software doesn’t just run through pallets 1, 2, 3, 4, 5, etc., sequentially,” Olsen says. “It has intelligence; it looks at everything that needs to be manufactured and when jobs need to be done.” When machining is complete, the software records an inventory of the finished parts and moves them out of the system and on to inspection and shipping.

Automating Inspection and Other Functions

When a seven-year contract for turned aerospace components required 100% inspection of all parts, Mach Machine bought a Hexagon Manufacturing Intelligence 7.10.7 coordinate measuring machine (CMM) with a full scanning head.

“Now that we have efficient manufacturing capabilities, we’re focusing on developing a first-rate quality department,” Olsen says. His facility upgrade plans include a fully enclosed inspection room and an addition to house more machine tools.

The inspection automation hardware consists of aluminum fixture plates with grids of 20 ¼-inch screw holes and ¼-inch dowel pin location holes mounted on the CMM’s granite surface table. Each job that goes to the measuring machine has its own unique fixture and instructions on where to place it on the grid. The operator drops the fixture into that location and selects the correct inspection program. The machine does the inspection and prints out a detailed report.

“We want to make it as easy as possible for the staff to verify their parts dimensionally,” Olsen says.

The shop conducts some on-machine quality probing, but prefers to perform inspection offline to keep the spindles running and producing parts. Olsen is exploring the possibility of integrating the automated inspection process with the flexible manufacturing system to provide feedback to the machine and enable in-process adjustments.

“I see another horizontal machining center with another Fastems system in our future,” Olsen says. “Our next big move is to automate some older machines through a form of robotics so we can run a lot of parts overnight.”

Other automation candidates include deburring heat sinks using pencil grinders and robots.

“We’re constantly trying to achieve consistency from part to part, delivery to delivery. That’s where the automation comes in,” Olsen says. “Anywhere we can automate something, I’m going to do it to help our productivity and repeatability.”

Benefits Outweigh Initial Investment

“I’ve always been a firm believer that if I need to buy a piece of equipment, I don’t buy just enough technology for what I need,” Olsen says. “I always try to buy more than I need because it gives me flexibility to grow. Every time we’ve done that, we’ve been able to use the technology at some point in time. It’s always in our tool belt, so when we’re faced with a challenge we can say, ‘We can do it like this or we can use this process.’

“Newer technology is faster and makes higher-quality parts. Once we went in that direction, we saw huge gains in overall performance. You might pay a little more upfront than buying something used, but you’re getting superior technology.”

New machines facilitate connectivity by often being plug-and-play. “Our machines are Ethernet-based, so they plug right into our network.” In addition to boosting productivity and efficiency, new equipment sets his business apart from the competition.

“People come in and they see our machines are nice, new and well-lit,” Olsen says. “That goes a long way.”

Finally, while a visitor can’t see it, those machines represent a business with staying power. In addition to illustrating the company’s emphasis on creative process development and automation, automated HMCs combined with a flexible manufacturing system provide financial stability. The technology is available 24 hours a day, seven days a week, 365 days a year.

“That resource is always there,” says Olsen. “It’s helped us create a level of financial stability that many traditional machine shops don’t have when they’re dependent on running VMCs.”

Sidebar

Wanted: Young People Willing to Learn

Why cultivating an image as technology-driven is important to recruitment and retention.

Rather than lowering head count, automation has had the opposite effect on Mach Machine, a job shop in Hudson, Mass., that manufactures precision part prototypes and production runs for customers in the high-tech, medical, aerospace, and defense as well as marine industries.

“We’ve been hiring right along because we’re able to produce so much more,” President Dan Olsen says of the effects of implementing a flexible manufacturing system (FMS). “That creates opportunities, whether they’re in shipping or receiving or in quality control.”

Similar to the changes that occur in any evolving industry, though, the skills required for traditional manufacturing compared to advanced manufacturing is changing.

“You don’t necessarily need operators standing at the machining center; but you do need people with engineering backgrounds, programming skill, and understanding of manufacturing and materials,” Olsen says. “With productivity so high, we’re able to make sure everyone is taken care of and well-compensated. That helps employee retention.”

For whatever reason, the public considers manufacturing as dirty and unsafe. It’s not surprising, then, that the most pervasive problem in manufacturing today is finding talented and motivated younger employees.

“That perception’s starting to change with more vocational technical schools focusing on advanced manufacturing,” Olsen says. “Also, facilities like ours are well-lit and clean, so kids are having some interest in coming into this industry. We focus on finding younger people who are motivated and able to learn.”

Mach Machine doesn’t have a formalized employee training program. Instead, says Olsen, “When we find people we like, we bring them on, we see how they perform, find out where their strengths are, and focus on those. I’d rather grab them now than look for them when we need them.”