Sheet Metal Fabricator Corners Tube Fabrication Market with Fully Automated System

A Nevada company became a single-source supplier after installing a fiber laser tube cutter and replacing a CO2 sheet cutter with a fiber laser cutter. With a fiscal year of April to April, B&J Inc. is on track to surpass its yearly sales goal by 20%.

Posted: February 3, 2020

Gambling’s probably the first thing that pops into your head when you think of Nevada, but the state also has a healthy manufacturing base. B&J Inc. is one such manufacturer, providing various industries with CNC machining, sheet metal, and powder coating manufacturing from a 54,000-square-foot facility in the City of Sparks in the Reno metropolitan area.

Incorporated in 1975 as a machine shop, B&J quickly established a reputation as a reliable supplier of high-quality components. This led customers to request sheet metal fabrication, which has become the company’s primary revenue source via assemblies for gaming equipment, water fountains, water safety equipment, operating tables, athletic equipment, and the automotive and medical industries.

Vice President Gregg Fisher joined the team in 1983 as a welder. Although he eventually married the CEO, Cherie Fisher, he worked his way up through the ranks in various positions. The experience gave him excellent insight into operations.

For example, he oversaw equipment evaluation and purchasing when virtually all fabrication was done manually, a 24-hour, six-day-a-week operation.

“I thought, ‘There has to be something better than this,’” he says. There was: B&J bought semi-automated lasers, fully automated punches, robotic press brakes, and robotic welding cells to complement its battery of CNC machining centers. All help keep overhead low and productivity high.

The company’s success partly stems from Fisher’s ability to capitalize on changing market dynamics.

The Reno area has been a well-known center for precision sheet metal fabrication since the 1980s, and there was stiff competition for jobs ranging from 250 parts to 10,000 parts. Then business began shifting to high-value, sophisticated one-offs and industrial-type fixtures where 500 parts is considered a large quantity. With virtually no tube-fabricating capabilities in the area, jobs requiring such work were being subcontracted out to California.

Fisher sensed a business opportunity.

Yet Another Function Is Automated: Tube Cutting

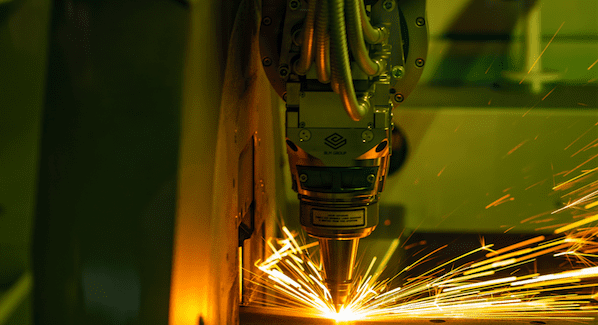

B&J decided to function as a single-source supplier. With this in mind, Fisher began researching tube cutters. After meeting with major machine manufacturers, he settled on BLM Group’s all-automatic LT7 Lasertube 3kW fiber laser cutter.

The machine cuts round, square, or rectangular tubes up to 6 inches (152.4 mm) in diameter, special sections, and open profiles. Accessible from the rear and upper side so material can be loaded with a bridge crane or forklift, other design features also streamline production. Loading chains can be quickly extracted from a rear standard bundle loader to load a single bar or open section. The loading and unloading systems also accommodate short and long parts.

Three programmable unloading positions save time by enabling B&J to separate out different pieces. Scrap is also managed independently, so it can be emptied without interrupting the machine.

At the end of each batch, the machine reconfigures itself for the next cycle: Loader, rear spindle, front bezel, and self-adjusting support guides automatically adapt to the new section to be cut. Several functions facilitate productivity and quality despite operator skill level by tracking and automatically adjusting various operations.

During cutting, for example, support guides automatically adapt to tube dimension and weight. An optical device calculates the compensation required to adjust the part program to maintain required tolerances despite irregularly shaped or bowed tubes. The machine manages all cutting parameters and adjusts focus configuration according to material and thickness during cutting, piercing, and marking.

Like many machine makers, BLM works to enable inexperienced operators to easily set up and run the laser cutter. They’re walked through the process of choosing appropriate parameters based on material type and thickness. CNC help topics on the machine include an instruction manual, maintenance tutorials, exploded part drawings to identify spare parts, and a video guide with how-to tutorials.

The machine’s Artube 3D CAD/CAM software allows operators to move from a design idea to a part in one click, design a more complex frame, or import other CAD programs. A monitoring system called Protube estimates cost based on batch processing time, prepares and sends work orders to the machine, and integrates with enterprise resource planning (ERP) systems.

“We saw lots of simpler machines and huge machines more suited for service centers,” he says. “But with advanced technology, a reasonable footprint, and easy setup, the LT7 was right in our sweet spot.”

Updating to Fiber Laser

Since B&J had an aging CO2 sheet metal cutter, BLM offered attractive pricing if B&J bought an LS5 sheet metal laser cutter in addition to the LT7.

The sheet cutter has many of the same features that make setting up and running consistent-quality jobs easy for inexperienced operators. It has a number of special nozzles to enhance performance on specific materials, and guides the operator through choosing and centering the appropriate one. It also automatically changes the nozzle, keeps it clean, and checks wear.

Perhaps most importantly for Fisher, it was the only machine with the configuration he wanted. In addition to accommodating transverse and in-line pallet changers, users can add automatic sheet loading and unloading or a storage tower for automated material type and thickness changeovers, and expand the machine to accommodate tube cutting.

Moving from CO2 to fiber laser for the two new machines required plumbing the shop for bulk nitrogen. This increased startup costs, but they’ve been offset by the ability to keep more work in-house and take on more work.

Typical components, such as one-off custom pallet designs for repetitive lifting procedures used in packing and assembly operations or industrial track equipment for vehicles, are usually comprised of steel tube varying from 0.75 inch by 075 inch to 6 inches by 6 inches. Before installing the tube cutter, B&J had to contract out a portion of a component or hand-saw the material. It’s now processed in less than two hours.

The sheet metal laser cutter was installed in May 2019 and the tube cutter followed a month later. After six months, B&J had already experienced growth. With a fiscal year of April to April, the company is on track to surpass its yearly sales goal by 20%.

Unforeseen Benefits

After a week of training at BLM Group’s technical center in Novi, Mich., B&J’s team was ready to run their new tube cutter.

“Aside from some need for manipulating the 3D models, the execution from programming to cutting was pretty flawless,” Fisher says. “We moved pretty quickly from doing straight cuts to some really cool killer angles.”

In addition to simple setup, the machine enables B&J to accurately estimate a job.

“When you’re competing in a world of one-offs, people want an answer to what it will cost very quickly,” Fisher says. “We can get a pretty good calculation of job cost within 40 minutes, which is hugely helpful in the sales process.”

Fisher explains that with sophisticated one-off parts, you need to pay a lot of attention to get it right the first time. “You have to slow down a little, but these are high-value, complex jobs.”

Additionally, the LS5 laser cutter allowed B&J to expand into cutting non-ferrous materials such as aluminum, copper, and brass, where Fisher also huge room for growth. “We’ve been in hiring mode ever since installing this equipment,” he says. “It’s both exciting and stressful.”

To help with the influx of work, B&J has hired a lean manufacturing coordinator for the first time to help level out the scheduling and ensure work gets out the door as promised.

The cutters streamline customers’ operations as well as B&J’s. Cuts don’t require grinding or other rework. Edges are ready for welding without additional preparation. Fab-form and locking-tab capabilities speed welding operations by enabling parts to bend or snap together.

“It’s important to me that a customer can walk in our shop and write one purchase order, knowing that quality, delivery – everything – is controlled by us from machining to fab to welding to powder coating to painting,” he says. “We build the entire product, and that’s what separates us from other companies in the area.”

BLM Group USA Corp., 46850 Cartier Drive, Novi, MI 48377, 248-560-0080, sales@blmgroupusa.com, www.blmgroup.com.