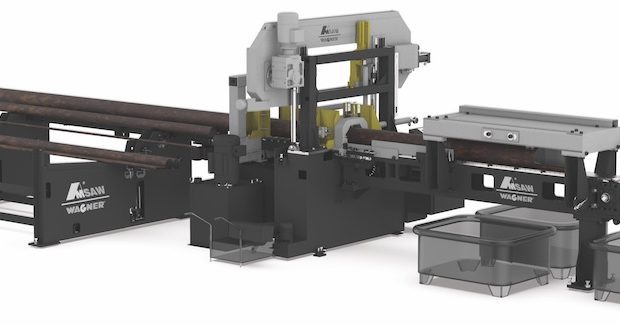

High-Production, Automatic Billet Saw

Using Advanced Machine & Engineering’s (AME) AMSAW Billet Saw, an operator need only load the table, unload the bins, input the required units into the computer, and change the blade. The saw handles the rest, including separating, transferring, measuring and cutting up to 5 tons of mixed round billets.

Posted: March 19, 2020

A new line of heavy-duty, dual-column bandsaws is part of Advanced Machine & Engineering’s (AME) (Rockford, IL) carbide sawing brand, AMSAW, diversifying their product offering of high-production sawing systems to become a one-stop shop for cutting technology.

The AMSAW WAGNER high-production automatic Billet Saw can load up to 5 tons of mixed round billets onto the table. Separated and transferred one by one to the power roller conveyor, billets are conveyed toward the measuring grippers of the saw then individually measured and automatically cut, based on the PLC inputs.

The cut pieces are separated by size and moved to a number of bins. The remaining bar, if not completely cut, is retracted and unloaded on a cradle opposite the load table. The next bar is then cycled the same way, until the table is empty. A saw operator is only required to load the table, unload the bins, input the required units into the computer and change the blade.