Meet the Juggling Juggernauts

Overwhelmed about where and how to start digitizing? Relax. Rome wasn’t built in a day, either.

Posted: March 20, 2020

EDITOR’S FORUM

Our theme this month is High Mix, Low Volume: Everyone’s a Job Shop Now. Economists and demographers say that, because we expect to find the product with every feature, finish, configuration, and size we want at the price we’re willing to pay, American consumers are the reason manufacturers are juggling more smaller-sized batches instead of fewer huge production runs.

Sometimes I wonder if you’ve spoiled us. We wouldn’t expect to get exactly what we want if you weren’t so good at producing it.

Capitalism has a way of doing that. If you like to read, I recommend P.J. O’Rourke’s Eat the Rich: A Treatise on Economics. (Trust me: It’s funny.) Before the fall of the Soviet Union, each factory got an annual gross-output target from the government and had to order materials and supplies from the State Planning Committee instead of each other.

“These entities worded as well as everything else worked in the Soviet Union,” O’Rourke writes, meaning not very well. Factory managers always ordered more than necessary hoping to get enough to move one step closer to meeting their production target.

And because it’s easiest to produce something in all the same size and/or same material, that’s what they did. This is why Russians automatically got in line whenever they saw people queuing up at a store—it meant something they needed might be available. Whether or not it worked or fit wasn’t the factory’s concern.

But I digress.

Everywhere you turn some vendor’s telling you to automate this and digitize that so you, your equipment and material suppliers, and customers become one single integrated design-and-delivery organism. Profits will increase because lean-manufacturing principles will have eliminated waste, and your customers will keep coming back because doing business with you is so easy.

That’s the ideal. Reality, of course, is messy.

Where to start? Choosing is overwhelming when you’re busy trying to get parts and assemblies out the door. Done thoughtfully, meaning you’re trying to streamline operations instead of jumping on the bandwagon because everyone else is doing it, digitizing is difficult.

Employees are the single biggest obstacle. Not because they’re actively malicious, but because…well, they’re human. We can’t be programmed like a machine or a robot because of our individuality.

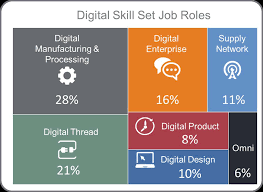

Which is just as well. No matter how many processes a factory automates, how many machines it connects and monitors, how much big data is generated and analyzed, growth isn’t possible without the creative spark that only the human brain is capable of. The employees who hold titles listed in the recent Manpower Group/UI Labs “Digital Workforce Succession in Manufacturing” report – predictive maintenance systems specialist, machine learning specialist, collaborative robotics engineer, for example – will need feedback from their colleagues on the shop floor to optimize operations.

That’s why speakers at a FABTECH 2019 Leadership Exchange recommended starting with your people. What problems would arise if you lost long-term employees? Who does what and does anyone else know how to do it?

Our two cover story subjects provide playbooks on how this works.

When it couldn’t find one it felt would meet its needs, Canadian sheet metal fabricator CMP Advanced Mechanical Solutions developed a digital work-instructions solution in-house. Imagine capturing and recording every single step for hundreds of assemblies in a way that makes sense for new employees as well as veterans. It’s mind-boggling.

The time and effort paid off with a subsidiary, Visual Knowledge Share (VKS), that other manufacturers worldwide are using to make assemblers as interchangeable as possible. It required hiring more than 20 software developers and investing more than $25 million in intelligent equipment and facility improvements, but CMP is considered one of the most advanced factories in North America. The business earned CMP a government award for innovation.

Like VKS, Mach Machine was launched to solve a problem for its parent company. President Dan Olsen wasn’t a machinist by training, but he figured out how to make parts customers wanted that other suppliers wouldn’t or couldn’t make. In his drive to free employees from performing mundane repetitive tasks, he’s automated processes when he identifies an opportunity to do so. Sometimes this is a little scary, but the investment’s always paid off. Implementing a flexible manufacturing system (FMS), for example, didn’t lower head count because the company’s taking in so much new business.

Our March issue is full of other examples of how manufacturers and fabricators are driving out wasted time and effort to make it as high-mix, low-volume suppliers. I hope you enjoy meeting them.