Precise Control of Double-Depth Positioning Processes

With the camera-based IPS 400i positioning sensor for high-bay storage devices, Leuze Electronic expands its IPS product range with a model for optical compartment fine positioning. A model for use in refrigerated warehouses is available.

Posted: March 23, 2020

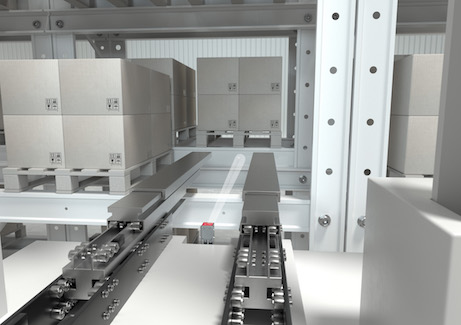

About a year ago, Leuze Electronic Inc. (New Hudson, MI) introduced the IPS 200i, the smallest camera-based single-depth positioning sensor, which is used for pallet-high racks and small-part container storage. Now, equipped with the market’s smallest camera-based positioning sensor for double-depth compartment fine positioning, another product – the IPS 400i – helps high-bay storage devices quickly and easily find the correct rack.

By detecting round holes or reflectors in single-depth and double-depth bars, the sensor determines the position deviation relative to the target position in the X and Y directions. This makes the unit particularly suitable for use in double-depth pallet high-bay warehouses. A model with integrated heating for use in refrigerated warehouses down to -30 degrees C is also available.

The sensor is put into operation using a web-based configuration tool with a user-controlled installation wizard. Printed configuration codes are read in without a PC via “Code Generator,” which means configuration adjustments can be made directly on the high-bay storage device. An alignment system consisting of four feedback LEDs further facilitates commissioning.

Due to its ambient-light-independent IR LED lighting, fault-free use in warehouse technology is possible with just one device for a working range of up to 2,400 mm. With its TCP/IP interface and Profinet RT (Real-Time) open industrial ethernet standard, the IPS 400i easily integrates into a network to enable quick, location-independent diagnostics.

Condition monitoring and predictive maintenance take place using a quality score that detects deterioration in the sensor’s reading performance at an early stage. This minimizes downtime and increases system availability and cost-effectiveness.