Contract Manufacturer: Single Operator Can Double+ Output

As part of a strategy to increase uptime, enhance the accuracy of machined parts, and expand the size of parts they can produce, J&R Machine installed two DMG MORI NZX 2000 automated CNC systems at its Shawano, Wis., headquarters. A single machine operator will be able to more than double his or her current output of complex parts.

Posted: April 3, 2020

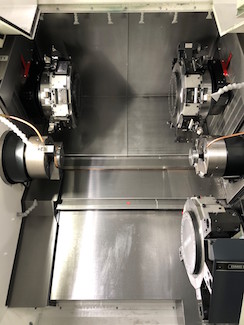

J&R Machine (Shawano, WI), a contract manufacturer focused on simplifying the production of complex machined parts, installed two DMG MORI NZX 2000 automated CNC systems at its headquarters. Committed to automation, the company will increase its production capacity for highly accurate and reliable machined parts, typically ranging from 1-10 inches in diameter and up to 28 inches in length.

Each high-precision, multi-axis turning machine features two spindles, three turrets, automated gantry loaders, and touch screen CELOS controls. The only DMG MORI NZX machines configured with a gantry system in the Midwest, they’ll increase production efficiency 20% to 35% and shorten lead times, depending on the part.

The new installation is the latest in J&R Machine’s strategic investments in manufacturing automation aimed at increasing uptime, enhancing the accuracy of machined parts, and expanding the size of parts J&R Machine can produce – all of which will enhance their customers’ experience with outsourcing complex parts. Other investments in automation include an auto-feed CNC sawing machine and software that provides actionable data to manage output and monitor production issues.

“From our collaborative culture to rapid response times, everything we do at J&R Machine is focused on simplifying the production of complex machined parts for our customers,” explains J&R Machine President Tim Tumanic. “This is especially valuable now as manufacturers work to address the unprecedented challenges in our current environment. The addition of the two new DMG MORI NZX 2000s strengthens our automation platform, increases employee efficiency, and results in greater accuracy of our customers’ parts.”

To continually enhance its manufacturing services and provide real value to customers, J&R Machine regularly invests in technology, plant layout, and operator training. The company’s current equipment configuration allows one operator to work on two single-turret machines simultaneously. With the addition of the new DMG MORI NZX 2000s, a single machine operator at J&R Machine will be able to more than double their current output.

The company has incorporated key features into their DMG MORI NZX 2000 configurations:

- Full horsepower and capacity on both spindles

- Capable of simultaneous turning/milling on main and sub spindle

- Three turrets with live mill/drill tool heads

- Y-axis for heavier cuts

- Auto-loading gantry for shaft and disc type parts

- Celos app driven control

In 2017, J&R Machine made a $2 million capital investment in four DMG MORI NLX2500SY sub-spindle lathes with axial and radial live tooling and four DMG MORI NLX2500Y with axial and radial live tooling. The two companies partner to develop configurations that allow J&R Machine to provide the highest level of service possible to OEMs and tier one or tier two manufacturers.