Machining Monster Tackles Wicked Difficult 3-Shift Forging

An Austrian machine shop specializing in forged steel parts expands to make installation-ready machining a standard service for customers that need one reliable go-to source. They, in turn, needed reliable machining tools tough enough to handle 24/7 forged parts – and found everything they needed in the BA 722 from Schwäbische Werkzeugmaschinen .

Posted: April 28, 2020

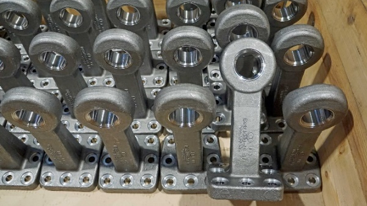

Forged steel parts are frequently used in applications with high sturdiness and reliability standards, such as drawbar eyes for agricultural machinery. Quenched and tempered steels are used for their excellent strength and robustness, but it means that high forces have to be applied to machine these materials. They also tend to form longer pieces of swarf, which are difficult to remove.

The standards for the machine tools used in the high-performance machining of these parts are no less stringent. Ferdinand Bernhofer GmbH is a medium-sized, owner-managed company in Austria that machines workpieces on a two-spindle machine from Schwäbische Werkzeugmaschinen GmbH (SW) (Schramberg, Germany).

“Our company specializes in drop forging in the weight range from 2.5 kg to 20 kg,” explains Engineer Ferdinand Bernhofer, owner and managing director of Technology of Ferdinand Bernhofer Ges. m.b.H.

Production is mainly in small to medium-sized series with batch sizes from 500 to 50,000 parts per year. The parts are delivered machined and ready for use upon customer request. Customers include manufacturers of vehicles (trucks and agricultural machinery), off-road vehicles (from construction machinery to dirt bikes) as well as general mechanical engineering companies and hydraulic system producers.

Forging is an extremely efficient manufacturing process in which the material is used to its full extent, which makes it a highly sustainable process. Bernhofer draws on its competence in the area of forging technology to collaboratively support their customers and optimize part design to ensure process compatibility.

Finishing machining for customer benefit

With this in mind, Bernhofer began ambitiously expanding its range of services several years ago. Expanding installation-ready machining to a standard service was a top priority. This service, which had previously been purchased externally, would be implemented increasingly in-house in the future.

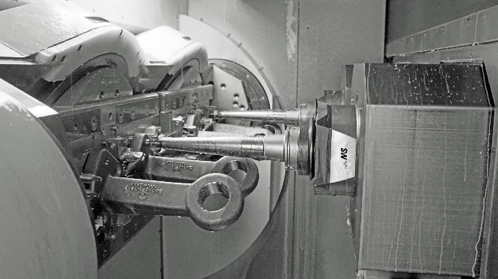

To do this, Bernhofer set out to find a manufacturer of suitable machine tools. Above all, the machine tools had to be sturdy and powerful enough to handle three-shift machining of forged parts that are often high-strength and therefore difficult to machine. The parts they machine are combined in groups so the systems can be changed over or retooled as quickly and smoothly as possible. Another criterion was the most extensive automation possible, in order to conserve resources through 24/7 operation.

Workpieces for motorcycle frames

“The first project was a family of parts with six variants made of quenched and tempered steel for motorcycle frames,” says Christian Stempfer, regional sales manager for Austria of Schwäbische Werkzeugmaschinen GmbH. “The goals were fully automatic machining and product change with no change-over. The BA 322 (a horizontal machining center from SW with two synchronous spindles), was chosen to accomplish these goals. The customer was so satisfied with the system that SW was honored with the Ferdinand Bernhofer Gesellschaft Supplier Award 2016 in the same year as the delivery.

“The mutual trust we have built on this foundation has led us to choose SW again for the next project,” says Bernhofer.

The new project involved machining particularly large drawbar eyes made of different variants of 42CrMo4. The task was made more difficult by the relatively large number of holes and fits that had to be machined and was further complicated by the need for cooling lubricant to drill the holes.

The milling machine type BA 722, purchased for this purpose, is structured similarly to the BA 322 already in use. The larger machining center, also with two spindles, was needed because greater quantities of material will be removed through machining than for the motorcycles – up to 3 kg of material from each drawbar eye, which may weigh up to 18 kg depending on the variant.

Although the allowances range from 5 to 15 mm, no problems were reported for the “workhorse” BA 722. Its two spindles are capable of removing up to two metric tons of material in an hour of rough machining, even with a material as difficult to machine as this one. Even so, the system can be used not only brachially but also for precision machining, for example in helical interpolation of semi-spheres for clutches.

“The support provided by SW was beyond impeccable,” says Bernhofer. “In the critical initial phase of the project, Christian Stempfer in particular was untiring in his dedication to eliminating initial glitches and optimizing processes, including time spent outside of regular working hours.

“The technical service provided by the SW technicians stationed nearby in Austria and their supply of replacement parts also left nothing to be desired,” he adds. “Help was also available through telesupport and online consulting.

Bernhofer gave high ratings for SW’s support and service and noted that it was refreshingly uncomplicated. The first system delivered proved to be so good that a second was ordered a short time later because the customer’s call-off orders had increased. And machine availability is excellent despite the high work load.

“I was also so satisfied with the BA 722 that we have already begun discussing more extensive automation for the coming year,” Bernhofer says.