Quality and Reverse-Engineering Tips During Social Distancing

Exact Metrology offers practical ways to maintain safe, effective production in the workplace. Maintaining a six-foot distance from others as well as frequent hand-washing and device sanitizing are critical.

Posted: April 12, 2020

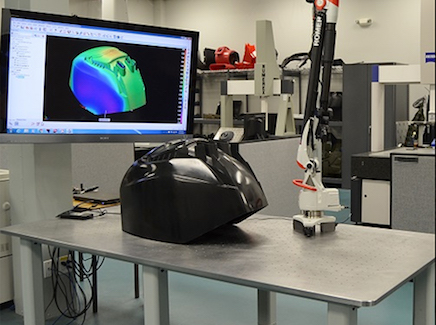

With much of the workforce operating from home, keeping up with quality inspection and reverse engineering is difficult during this time. However, there are solutions to counteract this problem. Some companies employ several of these tactics daily, but in these trying times they are much more relevant to maintain effective production.

Exact Metrology (Cincinnati, OH) offers the following helpful safety tips for metrology workers during the COVID-19 pandemic, courtesy of Jason Kleinhenz, marketing and training manager.

- If you are in the workplace, follow all the stated guidelines. These include staying 6 feet away, washing/sanitizing touched surfaces and washing your hands. Also remember to clean the objects you’re working with such as data collection tools and computers.

- Only one person should collect the data from the object(s). That person is responsible for handling the objects and the data collection tools. Of course, the designated person also needs to clean and sanitize all objects, tools and surfaces.

- Workers must save and upload data sets (and/or workspaces) to the cloud. Due to security threats, a company’s IT team should use a virtual private network (VPN) and/or file transfer protocol (FTP). This reduces the chances of data being hacked or stolen.

- Have another person, or a team, work separately to download (receive) the data sets, or workspaces and process them. They will have their own safety procedures in place (essentially the same as the data collector). If possible, the processing person(s) should write programs at the same time the data is collected. This saves time and money as two operations are occurring at the same time. Most likely, this is not possible in reverse engineering projects. However, in quality inspection projects, this is a massive time-saving practice.

- Communicating between the collector and processor(s) can be done quickly and virtually with online services like Skype and Zoom. The good old-fashioned phone works well for quick conversations too. There are some software packages that allow seamless workspace sharing between different people and teams such as a package through PolyWorks by InnovMetric

These techniques and tools can help companies reach their quality and reverse engineering objectives during social distancing. Exact Metrology is available at 866-722-2600 to answer questions about how to maximize efficiency or help with projects.