Compact Tube Configurations Made Simple

tranfluid’s MB 642 mobile bending machine will fabricate all kinds of tubes used in hydraulics, including those with thin tube walls. But this bending system is so compact, all you need is one square meter of production area in which to operate.

Posted: May 11, 2020

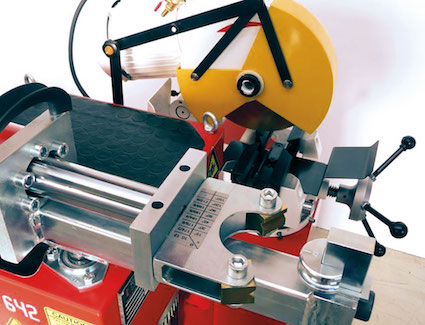

The transfluid MB 642 mobile bending machine has a bending system, and either a circular saw or a deburring unit can be added. transfluid, a Schmallenberg engineering company, offers accessories for cutting ring pre-assembly and flaring complete the range of possibilities.

All tubes that are used in hydraulics can be bent with this machine, including those with thin tube walls or pressure pipes with thick walls. It can also process tubes up to 42 mm and wall thickness up to 4 mm, or a 38×6 mm tube.

“What is special about our mobile bender is that it offers all the functions you need for hydraulics tubing and it only needs a very small production area, just one square meter”, explains Stefanie Flaeper, sales managing director.

“With this machine you can produce extremely compact tube configurations. No other machine can achieve the same compact tube processing”, says Flaeper.

The bending radii are 2-2.5xD on average. Occasionally, a 3xD radius is achieved with tubes with thin walls. The machine has a compact bending head and the tubes move in an empty space, so there are no collision points with the machine.

The bending angle adjustment on the transfluid MB 642 bending machine makes it possible to produce bends with precise bending angles. It is not necessary to have a straight area between the bends, which means the complete bending geometry can be extremely compact. These tubes do not have a swivelling range, so very long tubes can be processed in very tight spaces. Because everything is compact, the machine is ideal for mobile use.

Trimming and cutting can also be done directly on the machine. The burring unit can prepare the tubes for further processing. Since tubes are usually supplied with the corresponding connections, the MB 642 has an integrated tool for cutting ring pre-assembly that can fit all the standard cutting rings on the market.

If it is necessary to use a flaring device, the user can switch out the cutting ring device by hand with a single operation, facilitating the smooth processing of different types of connections. Simple to use, the transfluid MB 642 requires no special training.