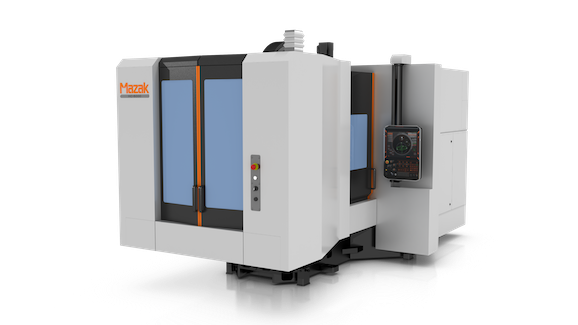

Easy-to-Use Horizontal Machining Center for Numerous Applications

Mazak’s HC-5000 4-axis horizontal machining center (HMC) boosts speed, output, reliability, and precision of numerous metalworking applications in nearly any production environment. Easy-to-program controls automatically calculate intersection coordinates and tool index positioning to optimize cutting.

Posted: May 6, 2020

The HC-5000 4-axis horizontal machining center (HMC) from Mazak Corp. (Florence, KY) offers power, flexibility, standard features, and options that make the machine an asset in any shop seeking to balance price, performance, and size.

Standard equipment includes traveling columns and full fourth-axis NC rotary tables to accommodate large and heavy workpieces. Diverse spindle options enable machining of aluminum, cast iron, and more: 12,000 rpm is standard; options include 15,000 rpm and 20,000 rpm speeds, all in 40 taper and BIG-PLUS 40 configurations. Tool magazine stores twice the tools – 84 – in the same amount of space as a 42-tool magazine.

The HC-5000 uses Mazak’s latest servo drive system with 1G axis acceleration for high machining speeds and superior accuracy. Core-cooled ball screws reduce thermal growth and achieve consistent positioning accuracy of linear axis movements. Advanced sensor technology promotes optimum stability and condition control, with sensors to monitor heat and vibration, along with other machine functions, for consistent high precision.

During extended hours of operation, Mazak Intelligent Machine Functions ensure stable and secure machining processes. For example, when ambient shop temperatures fluctuate, Thermal Shield automatically compensates via exhaust ducts that channel heat out and away from the machine and adjacent equipment.

MX Hybrid Roller Guide System eliminates stick and slip for higher positioning accuracy and offers nearly twice the rapid traverse rate of boxways while reducing coolant contamination. Greater surface contact accommodates large loads and provides better vibration damping, while the X-design improves distribution of load points by applying the load in four directions.

Mazatrol SmoothG CNC offers both EIA/ISO and Mazatrol conversational programming to ease complex part-production operations such as off-centerline machining, angled drilling, milling, and tapping.

With Mazatrol, inexperienced operators program the machine by answering simple questions about criteria including material type, O.D./I.D. dimensions, and part length. Quick Mazatrol imports 3D CAD models and automatically extracts coordinates to simplify programming, while Quick EIA plots interference-free toolpaths.

Mazatrol automatically calculates intersection coordinates and tool index positioning while it optimizes cutting conditions and machining processes. For compatibility with control programs created for other machine brands, Mazatrol uses the same G-codes as conventional EIA CNC machines. To run programs from other machines, operators simply edit M codes and confirm axis strokes along with cutting conditions.

For streamlined data entry and reduced programming times, the Mazatrol SmoothG touchscreen control minimizes the number of displays. Five home process screens – programming, tool data, setup, machining and maintenance – display data, with touch icons for quick navigation to additional displays.

Mazatrol SmoothG CNC features and functions include Virtual Machining, which allows operators to evaluate part programs before they begin to cut. High Gain Feed Forward Control boosts machining speed and accuracy, Fast Rotary Axis Speeds optimizes gear skiving and rotary axis threading, Variable Acceleration Control calculates optimal acceleration for multiple axes, Position-Controlled Hobbing manages hobbing and skiving operations, and Real-Time Tuning maintains optimal machining balance as workpiece weight changes.

High-pressure and Superflow coolant systems allow for increased cutting speeds, extended tool life, and efficient chip evacuation. Chip conveyor designs handle a wide variety of chip shapes and materials including aluminum, steel, and cast iron. Work air blasting removes stuck chips from the fixture and workpiece. A mist collector helps reduce maintenance costs and ensures a clean, safe work environment.

Automatic non-contact tool length measurement and tool breakage detection reduce overall part setup time. And with a Renishaw OMP60M touch sensor tool mounted in the machine spindle, operators can shift coordinate values to align workpieces automatically.