How to Optimize Sawing Operations

A sawing specialist asks and answers four basic questions about feed rate and feed pressure, blade life, determining cutting feed and cutting speed, and optimizing tooth selection.

Posted: May 15, 2020

DEPTH OF CUT COLUMN

BY JAY GORDON

Here are some tips answering common questions when sawing a range of materials and shapes.

What’s the Difference Between Feed Rate and Feed Pressure, and Why’s It So Important?

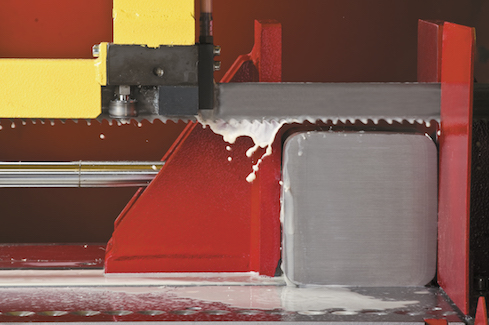

The two components of the sawing process are feed rate (traverse control) and feed pressure. Feed rate is how fast the blade moves through the material; feed pressure is how much force is applied as the blade moves through the material.

Both depend on the material and are typically set as opposite values.

For example, significant pressure isn’t required to cut aluminum and 1018 mild low-carbon steel because the blade’s teeth easily penetrate such soft metals. Thus, you’d use a relatively high feed rate at low pressure.

You’d take the opposite tack for hard metals. A slow feed rate at a higher pressure enables teeth to penetrate without forcing the blade to cut too fast, which could cause crooked cuts, poor life, and stripped teeth.

How Do I Find the Appropriate Cutting Feed and Speed for a Material?

Once a saw blade is properly guided, it’s imperative that the feed and speed of blade and saw are calculated to the bandsaw manufacturer’s recommendations to cut metals of various hardness levels and shapes. This will optimize the blade – and, ultimately – machine performance.

Materials are broken into three general categories with the following rules of thumb:

- Easy-to-saw, soft metals such as low-carbon steels and nonferrous materials tend to require higher blade speeds (in the range of 300 feet per minute/fpm) and higher feed rates and lower feed pressure.

- Moderately-difficult-to-saw metals such as high-carbon and tool steels require lower blade speeds (in the 200-fpm range) and mid-range feed rates with an increase in feed pressure.

- Difficult-to-saw metals such as heat-treated, nickel-based alloys and some stainless steels require even lower blade speeds (in the 100-fpm range) with lower feed rates and increased feed pressure to promote proper chip engagement.

Remember that these are approximations. Speeds and feeds should be adjusted for each job and material type/shape to optimize the cutting process by averting chip welding, crooked cuts, tooth strippage, and blade breakage.

What are Some Guidelines for Optimal Tooth Selection?

Material shape and thickness are important to consider when choosing the appropriate saw tooth, as is whether you’re cutting bundled or nonbundled material. Decisions should be based on the particular application’s requirements.

One rule of thumb is to have no fewer than three teeth and no more than 10 to 14 teeth in any given material at all times. However, because each application is unique, that’s a generality.

Here are some tooth-selection recommendations for various materials and applications:

General and light-duty cutting. Blades with a standard 0° rake tooth with variable pitch (5-8 to 10-14 ) are less prone to strippage and can take the abuse of nonproduction applications.

High-production cutting of solids and heavy walls. Depending on material size, a variable pitch (.8-1.3 to 14-18) with aggressive positive rake (up to 12°) profiles or an M-42 high-speed edge with 8% cobalt.

Cutting nickel alloys, stainless steels, and heat-treated steels (up to HRC 45). Variable pitch teeth (1-2 to 4-6) with positive rake (up to 12°) and surging cutting action. These materials come in many different shapes and sizes, but the same rule – no fewer than three teeth in the material at all times – applies.

Interrupted cuts on beams, channels, and tubes. A variable pitch (2-3 to 6-10) positive rake tooth with M-42 with 8% cobalt teeth.

When cutting bundles, base pitch on the average of thicknesses being cut. For example, an I-beam’s web and flange usually differ in size. Depending on the saw and how the material is being cut, the difference can be dramatic. While basing tooth selection on the average thickness of both isn’t a perfect solution, it facilitates production and extends blade life.

Tooth pitch depends on the material. For example, when cutting a bundle of ¼-inch angle iron, there’s typically a solid grouping in the middle with the arms of the angles sticking out to the sides. Selecting a tooth pattern based on the largest section in the middle will maintain production rates and minimize tooth strippage.

For tubing, base tooth selection on wall thickness and the thickest part of the bundle. For example, when cutting four 2-inch-square tubes laying side by side, remember that at some point the blade will cut across 8 inches before cutting into the walls. There’s no exact formula, a baseline can be determined by averaging the size of the material and adjusted accordingly going forward.

What’s the Best Way to Determine Blade Life?

Knowing standard blade life is as important as deciding which blade to use. First, blade life enables you to monitor life and note when it declines in order to determine and solve problems. Second, it allows you to compare blades and choose the best one for your application.

The most common and accurate way to determine blade life is by counting square inches. This allows an accurate representation of true life, no matter the size of the material. Counting parts, tons, hours, or days is acceptable but tends to be less accurate because materials typically change and thus a true accounting of life is more difficult to determine.