Manufacturer of the Year Outlines Company’s COVID-19 Response

At least one of this Georgia sheet metal fabricator’s 130 employees has tested positive for the coronavirus. President Bruce Hagenau shares how METCAM is keeping the rest of the team – and their families – safe.

Posted: May 15, 2020

METCAM President Bruce Hagenau was dealing with the coronavirus weeks before Georgia Gov. Brian Kemp ordered residents home as of April 3.

Hagenau co-founded the ISO 9001- and 14001-certified fabricator of precision sheet metal components and assemblies for OEMs such as Caterpillar, Carrier Corp., CommScope, and Tyco in 1989. In 2018, commitment to continuous improvement earned METCAM (an acronym for Metal and Computer-Assisted Manufacturing) three awards in its drive to lower rejection rates to 50 parts per million (ppm). Its commitment to sustainability has also been recognized by the county and state.

Hagenau’s been working from home since February. He self-quarantined after experiencing symptoms and plans to take the antibody test. In the meantime, he’s dedicating himself to helping other manufacturers keep their operations safely running.

As a Next Generation Manufacturing of Georgia advisory board member, Hagenau leads the organization’s thought-leadership panel. On April 23, he and representatives from three other manufacturing companies shared their companies’ pandemic-response experience during a webinar.

As of that date, one of METCAM’s 130 employees had reported mild symptoms and was sent home. The employee’s work station and those nearby were disinfected, and the health of employees in this work area is monitored. Confirmed positive on April 21, the second-shift employee must test negative before returning to work.

Orders are still strong, so METCAM’s running at full capacity even though about 30% of employees have opted to stay home. The key to keeping it all together, says Hagenau, is constant communication and reinforcement.

“Our objectives are threefold: ensure the safety of our employees, their families and visitors to our facility; do our best to help prevent virus spread; and continue to operate our business for the benefit of both our employees and our customers,” he says.

To accomplish our objectives, the company’s focusing on the basics:

Keep Your Distance

- Markings on the floor near time clocks are 6 feet apart to maintain distance between employees as they clock out

- Floor markings in the break room separate employees waiting on microwaves

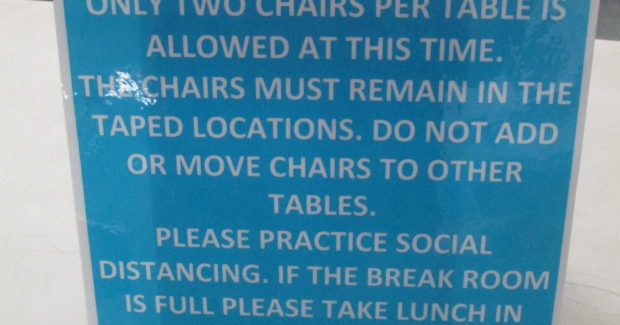

- Chair markings and signs on tables allow two chairs per table … spaced apart

- Employees are encouraged to eat lunch in their vehicles as much as possible

- Limit the number and size of meetings

Wear Your Mask, Wear Your Mask, Wear Your Mask

Keep Clean

- Wash hands regularly as prescribed

- Use disinfectant sprays to keep work area and work surfaces cleaned

- Wipe down anything an employee touches or handles, including keyboards, touchscreens, and tools

- Prop doors open wherever practical

Take Care . . . if symptomatic

- Stay home or go home!

- Communicate with HR

- Follow any and all requirements for isolation, testing, and return to work.

“We’re also using touchless thermometers for those who return to work after being required to stay at home,” he says. “We’re considering using touchless thermometers to monitor the entire workforce.

“We should soon receive electrostatic disinfectant sprayers to more quickly treat larger areas of our plant, particularly in high-use areas and areas where someone has shown symptoms.

“The idea that a challenge is an opportunity for progress is one I really embrace. Everyone is dealing with the adversity of this pandemic, and our commitment to continuous improvement and greater efficiency is designed to operate through both thick and thin.”

Click here to read the pandemic response plan of Covington, Ga., plastics manufacturer SKC Inc.