Modular Toolholder Simplifies Swiss-Style Machining

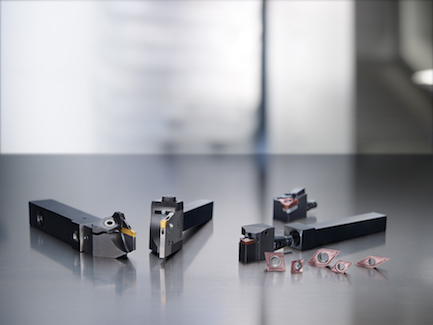

Seco Tools’ quick-change system enables fast, easy, and repeatable insert indexing and tool changes outside of tight machine work spaces. Both cutting heads and inserts can be removed as a single assembly for quick indexing and reinstallation.

Posted: May 18, 2020

The QC (quick-change) modular toolholder system from Seco Tools (Troy, MI) improves productivity of Swiss-style machining by enabling fast, easy, and repeatable insert indexing and tool changes outside of tight machine work spaces. The toolholder also features Seco’s Jetstream Tooling and Jetstream Tooling Duo technology for optimal chip control, high-quality surface finishes, and longer tool life.

The toolholder allows users to remove both cutting heads and inserts as a single assembly, quickly index them, and reinstall. Manufacturers may also use the system to exchange cutting heads and inserts with a second set for even greater efficiency. Cutting head’s double-carbide pins ensure accurate, consistent, and secure insert mounting and indexing.

Jetstream Tooling technology precisely directs high-pressure coolant through the toolholder to the cutting zone. Available on a selection of cutting heads, Jetstream Tooling Duo adds a second coolant channel to the holder’s underside that can be switched off if needed for even more versatile machining.

The toolholders include cutting heads for general ISO turning, MDT, threading, and parting-off. Shanks are available in 10 mm, 12 mm and 16 mm as well as 0.37 inches, 0.500 inches, and 0.625 inches.