New Grooving Toolholder Ideal for Small-Part Machining

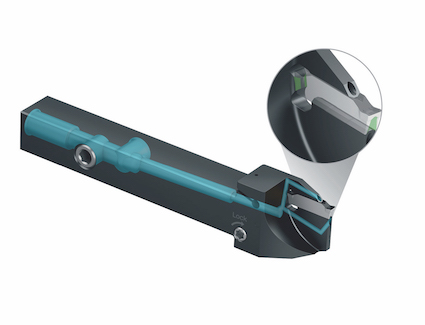

Change inserts approximately 70% faster with Walter’s G4014-P groove turning holder and double-edged DX18 indexable inserts. ‘SmartLock’ feature enables users to access the clamping screw from either side.

Posted: May 18, 2020

Designed for producing small parts via Swiss-type machining, the G4014-P grooving toolholder from Walter USA (Waukesha, WI) features SmartLock insert clamping, which lets users access the clamping screw from the right side or left side. By making operation from either side of long-center lathe and multispindle machine tools possible, changing inserts is approximately 70% faster.

The insert seat’s positive-engagement prismatic design prevents incorrect engagement, especially for narrow insert widths, and enables an extremely high level of indexing accuracy. Clamping forces that are around 30% higher than those of existing tools on the market increase stability and significantly prolong tool life.

The grooving system consists of G4014-P and DX18 inserts. Available in shank sizes of ½ inch to 5/8 inch and 10 mm to 20 mm, with insert widths from 0.059 inch to 0.118 inches (1.5 mm to 3 mm) and for parting-off diameters up to 1.38 inches (35 mm).

The holder designs are offered with precision cooling on the rake and flank faces or without internal cooling. These special features make the system the benchmark for mass production of small parts like shafts, plug contacts, nozzles, and implants for the automotive, electronics, medical, watchmaking, and general engineering industries.