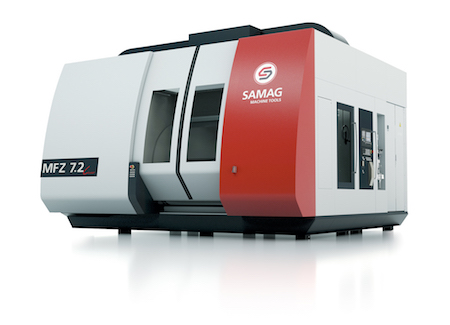

Samag Machining Centers and Deep Drilling Machines Available in North America

German Machine Tools of America (GMTA) is selling the full line of Samag MFZ Series multispindle machines for high-volume cubic workpieces. Applications include knuckles, engine blocks, gear boxes, valves, and connecting rods for the automotive powertrain, truck, and off-highway markets.

Posted: May 6, 2020

Based in Saalfeld, Germany, with offices and service centers worldwide, Samag supplies complete turnkey packages – tooling, workholding, robotic articulation, parts handlers, and transfer mechanisms – for high-production work such as knuckles, engine blocks, gear boxes, valves and connecting rods.

German Machine Tools of America (GMTA) (Ann Arbor, MI) is selling Samag’s MFZ Series horizontal machining centers (HMCs) in the North American market.

With FIT 2 PART, the X, Y, and Z-axes of the 2-spindle machine can be corrected independently of one another. Four sizes and two drive types offer options for high-speed machining and heavy-duty cutting. The number of spindles, the variable distance between them, and the extendable tool magazine allow the machining of diverse workpiece dimensions and capacities.

All models are available with a linear or ball screw drive and up to four working spindles. Five-axis simultaneous machining and a workpiece feed during primary processing time are possible.

The rock-solid machine bed is thermally stable and features damping capabilities. Users benefit from productivity increases, flexibility, greater precision, and energy-efficiency.