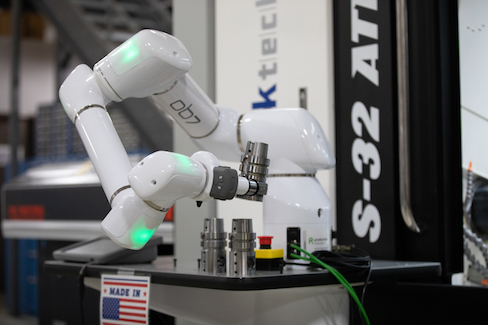

Extended-Reach Cobot

The OB7-Stretch from Productive Robotics extends 1.25 meters, but with a payload of 4kg, it offers an affordable alternative to bigger-payload, long-reach cobots. Its seven axes design gives it a dexterity with which to circumvent obstacles.

Posted: May 4, 2020

Simple to use and affordable to buy, OB7-Stretch is the fourth model of Absolute Machine Tools’ (Lorain, OH) partner Productive Robotics, Inc.’s (Carpinteria, CA) next-generation teachable collaborative robots (cobots), and it’s designed with a longer reach to handle parts and machines with longer distances. Similar to the standard OB7 5kg model, it has a longer reach of 1.25 meters and a slightly lower payload of 4kg.

“We have many customer’s applications that need a bit more reach, but have lighter payload needs,” says Zac Bogart, president of Productive Robotics. “OB7-Stretch was designed for those applications.”

Applications that require a longer reach to pick up a part or reaching deeper into machines will benefit, particularly in those in plastics molding, packaging, and palletizing. In CNC machine tending, OB7-Stretch can tend multiple machines at one time when the robot needs to reach more than one machine, and when the robot needs to reach deeply into a machine.

While Productive Robotics has two larger models with longer reaches, OB7-Max 12 (12kg and 1.3 meter reach) and OB7-Max 8 (8kg payload and 1.7 meter reach), OB7-Stretch is a cost-effective alternative to the higher payload and reach robots – it’s priced the same as the standard OB7 model ((5kg payload and 1 meter reach).

“We’ve had a lot of requests for a reasonably priced collaborative robot with a longer reach than is available on the market. OB7-Stretch is that product,” says Bogart.

All the OB7 robot models are built with seven-axis capabilities – like a human arm, seven joints give OB7 the flexibility and dexterity to reach around objects or obstacles where others can’t. But unlike a human arm, each of OB7’s joints can rotate 360 degrees in both directions allowing the cobot to work in more confined workspaces and areas that a six-axis robot can’t reach.

OB7s feature a “no programming,” simple, teaching platform – the user simply shows OB7 how to do the job and OB7 learns.

Software Update Adds 50 Operational and Ease-of-Use Features for Cobots

As of May 2020, software updates add 50 operational and ease-of-use features to the line of OB7 collaborative robots from Productive Robotics. The software updates enhance the cobots’ connectivity, expedite efficient integration with other equipment, and facilitate real-time status monitoring.

Included in the list of new and upgraded features is full linear control that broadens the cobots’ “no-programming, no coding,” simple-to-teach intelligence. The updated software also strengthens the cobots’ ability to directly monitor and control the machines they work with, including providing instant connection to equipment with Rockwell Automation’s Ethernet IP. Live online monitoring with email and text alerts provides real-time updates and notifications of machine stoppages or other issues. Complete interoperability with Cognex and other smart camera systems expedites systems integration.

With seven axes, OB7 cobots have extended flexibility that enables them to reach around obstructions and operate in confined workplaces. The family of four different OB7 cobots is engineered to accomplish simple to complex tasks for various payloads and sizes. Because they are manufactured in the U.S., Productive Robotics cobots benefit from fast, reliable technical support and part supply services.

Productive Robotics products support Absolute Machine Tools’ commitment to providing comprehensive engineering assistance for custom-tailored automation, robotics and turnkey machining solutions aimed at reducing manufacturing costs.

“Productive Robotics is an innovative leader in the development of next-generation collaborative robotics technology,” says Courtney Ortner, chief marketing officer at Absolute Machine Tools. “With this new software launch, Productive Robotics reinforces that the OB7s are the smartest, simplest to use, and easiest to deploy 7-axis cobots on the market.”