The Problem With Particle Porosity and How to Fix It

3D printing powders maximize part quality, but many are the suppliers from which to choose. In this Q&A, the president of GEMCO notes the industry is turning to contract powder processors for sophisticated heat treatments that improve quality.

Posted: May 15, 2020

BY CASEY MUENCH BICKHARDT

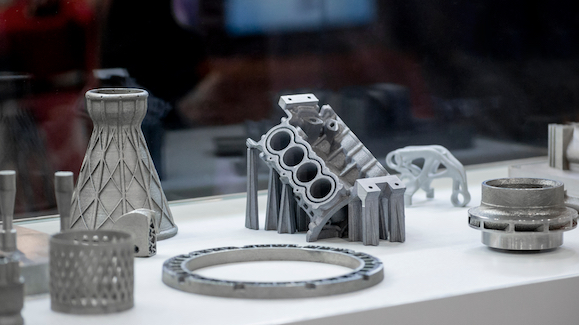

Three-dimensional (3D) metal printing applications range from aerospace, defense, and automotive components to medical devices and jewelry. Materials range from aluminum, titanium, stainless steel, cobalt-chrome, copper or nickel alloys to precious metals such as gold, silver, platinum, or palladium.

Whatever the material, parts are created from digital specifications by laying down layers of metal powder and using a laser to fuse the particles until the part is complete. Like ink-based printers, 3D metal printing has its own consumables – in this case, powder consisting of extremely fine, submicron particles.

Although there are a wide range of powder suppliers, the industry is turning to contract powder processors for sophisticated heat treatments that improve quality. As 3D printing techniques and equipment continue to advance, this can improve powder flowability to prevent clogging, speed the process, and produce a higher-quality part.

Casey Muench Bickhardt, president of tumble-blending and vacuum tumble-drying equipment manufacturer GEMCO (Middlesex, N.J.), explains how.

Q: How fast is the 3D metal printing market growing?

A: Grand View Research Inc. expects the global market to reach $3.05 billion by 2025. But to efficiently produce high-quality parts, powder producers and printer manufacturers must ensure consistent, repeatable powder quality.

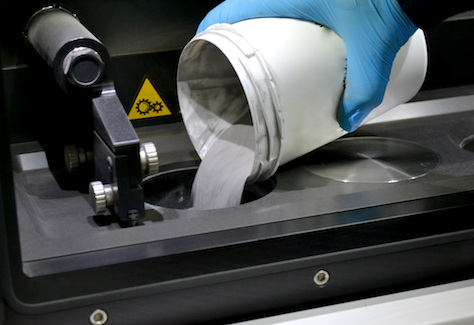

Q: How are the powders produced?

A: Most are produced by gas atomization. A feedstock is melted in a crucible and ejected from a nozzle into a high-pressure gas stream. This breaks the molten metal into fine particles ranging from 50 microns to 150 microns.

Q: Why is powder flowability so critical?

A: For reliable 3D printing production, powder must flow continuously and smoothly. Particles should be spherically shaped to pack most efficiently, but surface porosity is equally important. Otherwise, the powder can clog or slow during the process, affecting printing speed and quality.

Q: Can anything impede flowability?

A: Rough or porous particles create more friction, which inhibits flow. The attractive force between the particles also increases as they become smaller. Therefore, finer powders flow less freely.

From a quality standpoint, particle porosity can reduce the finished part’s load-bearing, fracture toughness, and fatigue properties. Under cyclic stress conditions, this can lead to cracks and failure.

Q: How can metal powder porosity be resolved?

A: A raw particle may have a porous, craggy outer surface. Heating it closes the pores so the particle is more spherical and flows more smoothly. As a result, a growing number of powder suppliers and printer manufacturers are adding steps to the manufacturing process.

For example, GEMCO’s in-house testing/engineering organization, Advanced Powder Solutions (APS), a contract manufacturer with extensive powder expertise, uses vacuum tumble dryers that provide sparging (gas injection) in addition to heat application. To circulate heat evenly amid the powder, a perforated tube is positioned under the material bed to distribute a flow of inert gas such as nitrogen.

The gas purge also keeps oxygen-sensitive or volatile powders from compromising certain alloy chemistries. Covering the material bed with a blanket of inert gas provides a protective barrier that prevents the powder from being exposed to atmospheric oxygen.

This improves operator safety as well. Nickel, for example, can be potentially dangerous in powder form. Containing such materials may be necessary to eliminate fire or explosion risk.

Q: Should fabricators reuse powder?

A: Yes. The material is costly, so they should add any unused metal powder at the bottom of the tray to new powder for the next print job.

Q: How is that done?

A: Vacuum tumble blenders apply even turbulence in all corners of the mix via a combination of macro and micro blending that better distributes the particles.

Macro blending is achieved by rotating the blender, allowing the material bed to fall away from the walls. The blender moves at a precise speed, with the vessel wall at a precise angle, so the material cascades over itself. There’s no additional force from paddles, plows, or spiral ribbons – just gravity.

While this occurs, micro mixing (if needed) simultaneously proceeds via agitator blades in the center of the mixing zone, where fine processing occurs. Together, the macro and micro mixing evenly expose each particle to six times more active blending per revolution than traditional mixers.

Although the industrial 3D printing market primarily involves metal powders, heat treatment can also improve part quality and manufacturing productivity in markets where plastic or resin-based powders are used.