3DEO Ships 150,000 Production Parts

Founded just four years ago, the milestone demonstrates 3DEO is realizing its mission in the metal additive manufacturing market.

Posted: June 15, 2020

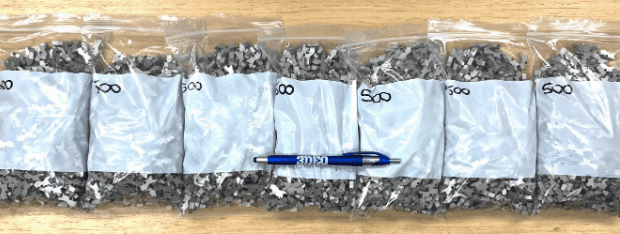

3DEO (Los Angeles, CA), a metal 3D printing technology company, has shipped 150,000 production parts for end-use applications. This represents a significant milestone for the company, which was founded in 2016 specifically to compete in high-volume metal manufacturing markets against conventional manufacturing techniques like CNC machining and metal injection molding.

“One-hundred and fifty-thousand parts is a terrific milestone for 3DEO,” says 3DEO President Matt Sand. “It validates our patented technology, our unique business model, and our mission to break metal additive manufacturing (AM) into high-volume production. Today, we routinely win bids against traditional manufacturing because of our competitive cost structure and material performance.”

Until recently, metal AM has found success only with prototyping and low volume production in high-value applications. These segments are only a fraction of the total market, limiting the true potential of AM’s impact in manufacturing. 3DEO’s mission is to make metal AM widely available for mass production. The company’s 150,000 pieces is evidence the company is realizing its mission and penetrating the high-volume market of metal parts.

“We are especially proud of the fact that every single customer we are working with is implementing metal AM in production for the first time,” says 3DEO CEO Matt Petros. “3DEO’s unique business model and patented technology are the keys that allow 3DEO to finally break through and win parts orders in high volume production where it was previously impossible.”